Should I use Wago terminal blocks to connect wires?

We have already reviewed many existing methods for connecting wires in a home electrical network. And they came to the conclusion that lately electricians have got irreplaceable helpers - all kinds of self-clamping terminals. Among all the products existing on the electrical goods market, Wago terminal blocks have proven themselves in the best way. Let's devote this article to them, and talk about the device, advantages, parameters, types and features of the use of such self-tightening elements.

Content

Device and technical parameters

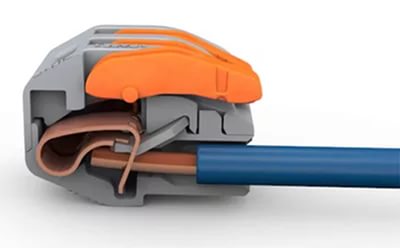

The terminal is a flat-spring clamp, which exerts pressure on the surface of the wire with its entire area and does not damage it. The Vago connecting clamp provides excellent contact due to the highly concentrated clamping force, which creates a low contact resistance over the entire contact surface.

For the manufacture of a current-carrying rail, electrolyte spring-hard copper with a soft tin-plated surface is used. The surface coating is performed with a tin-lead alloy (60% tin and 40% lead), which protects against corrosion for a long time.

For the manufacture of clamping springs, high quality austenitic chrome-nickel steel is used, it has a very high tensile strength.

Polyamide is used as insulating material. It has several advantages:

- absolutely neutral to corrosive processes;

- it has the property of self-extinguishing;

- highly flammable.

For Vago terminal blocks during operation, the lower temperature limit is -35 ° C. The upper temperature indicator of short-term exposure is from 170 ° C to 200 ° C (depending on the type of terminal block).

Connectors of this type are used not only in household electrical networks, but also in industrial production. Therefore, their technical characteristics have a very wide range of values:

- cross-section of the wires to be connected - 0.08-95 mm2;

- operating voltage - 100-1000 V;

- rated throughput current - 6-323 A.

Advantages of terminal blocks

Wago terminal blocks have an impressive number of advantages:

- They do not require any maintenance during operation.

- There is a separate terminal clamp for each of the wires to be connected.

- The connection does not require additional insulation.

- During operation, self-clamping terminal blocks of this type are absolutely safe, since they completely exclude the possibility of a person touching live parts.

- At the point of contact, the connection is gas-tight, which excludes any possibility of oxidation of the bare cores.

- To connect wires using such terminal blocks, an electrician does not need to make any additional efforts or have special knowledge and skills. Installation is fast and accurate, you don't even need to use a simple screwdriver. This is a huge advantage in cases where wiring has to be installed in hard-to-reach places and in large volumes, or work in poor light conditions.

- The Vago connecting clamp has compact dimensions.

- If necessary, the connection can be easily redone.

- Due to the springs, Bago terminal blocks are shockproof and highly vibration-resistant.

- They withstand excessive humidity, exposure to an aggressive environment (for example, fuels and lubricants) and high temperatures (since they are made of materials of the category of hardly flammable).

- Since the spring terminals are adapted to the specific conductor cross-section, the applied clamping force is optimal.This eliminates the possibility of temperature deformation or damage to the wires. Thus, Wago terminals provide a reliable contact connection for the entire period of operation.

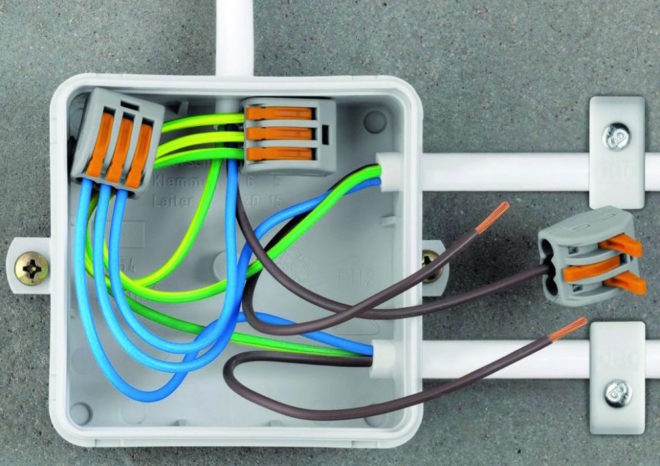

- In a junction box with such connectors, order and aesthetic appearance are always guaranteed.

- And, of course, a plus that all terminal blocks have is the ability to connect wires from different metals (for example, copper + aluminum).

The only drawback is that the connectors should be located in places accessible for inspection and work at any time. But not only Vagov terminals have such a disadvantage, it is inherent in absolutely all detachable connections.

Types, types, series

All produced terminal blocks are divided by the manufacturer "Wago" into different series. They are classified by the type of wire for which they are intended. Also, the clamps differ in that some series are completely filled inside with paste, while others are produced without it.

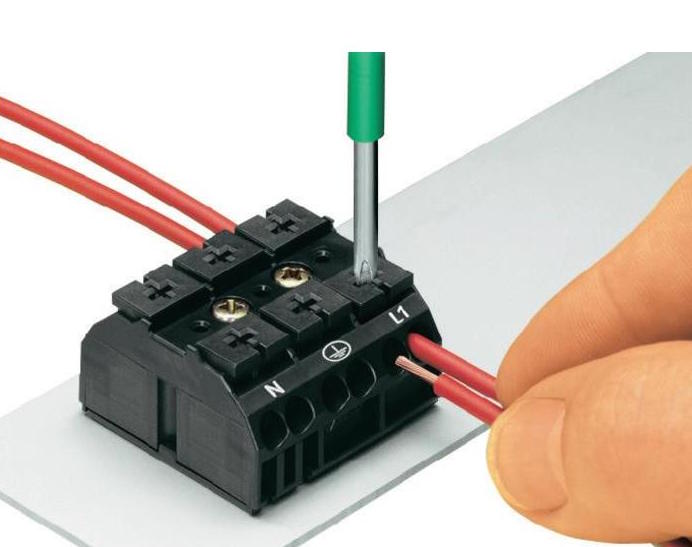

And one more difference between terminal blocks by the type of clamp:

- flat spring (the wire is attached under the spring plates);

- CAGE CLAMP (flat clip);

- FIT - CLAMP (clamp by cut-in contact).

Terminal blocks connecting clamping firms "Wago" are most widely used for connecting lamps, for connecting wires in junction boxes and shields. Let's consider the most popular models.

Features of the 733 series

There is a cheap type of terminal blocks, which is marked Wago 733. This series is designed for one-time switching of conductors. They do not have a lever, and the wire is fixed inside the terminal block with an internal lock, it kind of bites the core and does not allow it to move in the opposite direction.

Terminal blocks of this type are designed for voltages up to 400 V, rated current - up to 20 A. They are used to connect single-core wires.

Some models are produced with a paste, which has a protective function and enables the switching of aluminum wires (it prevents oxidation). These models are gray.

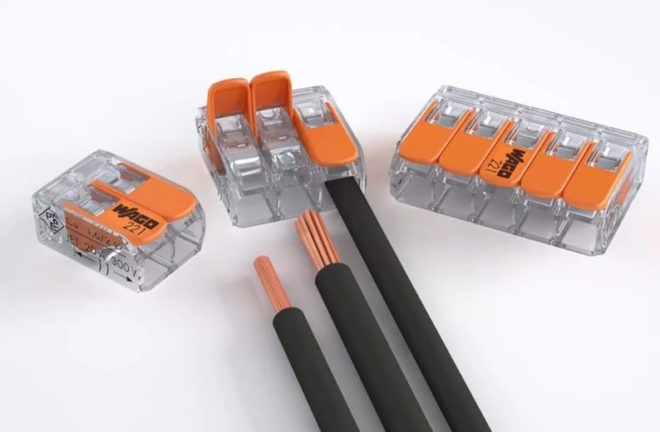

Clamps without paste have transparent bodies and colored inserts. The model with a transparent case is considered more advanced, since it makes it possible to control the process of connecting the core, as well as the quality of its fixation in the terminal block.

There are two options for connecting copper to aluminum in the 733 terminal block. Buy a clamp without paste and purchase separately conductive paste, which you insert into the socket where you will connect the aluminum core. Or vice versa, get a clip with paste and thoroughly clean it in the slot where you will need to insert the copper wire.

The switching process is very simple. The core must be stripped from the insulating layer by 10-12 mm and inserted until it stops.

You can remove the wire itself by scrolling, but you will need to make a lot of effort. It is clear that you will no longer be able to use this clamp in the future, since when the wire is removed, the fixing contact of the internal lock is deformed in it.

Wago 733 series clamps are available in variations from two to eight switched wires.

For the 733 series, see this video:

Features of the 222 series

To switch stranded wires, terminal blocks of the Wago 222 series are used.

These clamps have a number of advantages over the others:

- They are reusable.

- The lever mechanism holds the wire firmly and securely in the clamp.

- Quick diagnostics of power supply faults. To ring and identify the damaged area, you just need to remove the wire from the clamp, make a continuity of this circuit and, if it is working properly, fix the conductor back. While twisting will require for such a diagnosis to remove the insulating layer, unwind the wires, then twist them again, insulate.

- On the terminal blocks of the Wago 222 series there is a special rectangular groove through which you can connect the tester probe and call the phase-zero, determine the operating state of the contact.

Terminal strips of this series have orange levers. The commutation is also very simple. The lever rises, thereby pressing the spring clip. The stripped cable or wire is inserted into the hole, after which the lever is lowered and securely fixes the core.

With this model, you can connect stranded wires with solid ones. Series 222 is produced without paste, designed for voltage up to 380 V, rated current - up to 32 A. It is used not only for lighting fixtures, but also in junction boxes.

For more information on the 222 series, see this video:

Other series

In the 273 series terminal blocks, you can connect up to three wires with a cross section of 1.5 to 4 mm2... They are equipped with a paste inside, which makes it possible to work with aluminum wires.

The 274 series is designed for lighting circuits, for wire cross-sections from 0.5 to 2.5 mm2... Models are available with and without paste (for copper conductors).

The 243 series can rightfully be attributed to the "micro" category, the operating current of such terminal blocks is up to 6 A.

The 862 series terminal blocks are used to work only with copper conductors, they can connect from two to five wires with a cross section of 0.5 to 2.5 mm2... The body of such a clamp can be mounted on any base using self-tapping screws.

Clamps of the s series are also available, in which you can connect wires without first removing the insulating layer on the conductors. Their principle of operation is based on the use of a cut-in contact. This is one of the latest developments of the Wago company, which greatly simplifies and speeds up the installation work.

A few tips for using Wago

If you are going to use such terminal blocks in lighting networks or in some others that have a current limit of up to 10 A, then use Wago clamps boldly, you do not need to know any nuances and subtleties here.

When using terminal blocks in a network with a load of 10 to 20 A, the cleanliness of the conductor surface plays an important role. In addition, a circuit breaker must be installed in the circuit (for 10, 13, 16 or 20 A).

With a load over 25 A, it is better to abandon the use of Wago terminal clamps, and use soldering, welding or crimping the wires.

You can independently strengthen the reliability of the connecting clamp, for example, Wago 733. If your load reaches its limit values, then proceed as follows. Strip the cores of the wires to be connected by 20-30 mm and insert them as expected into the terminal block. Now, by turning the clamp clockwise, twist the remaining bare wires and insulate them. Rest assured, the reliability of such a contact has increased several times.

How to distinguish a fake?

The manufacturer Wago has established itself in the best possible way in the electrical goods market. In order not to buy a cheap fake, check out the differences between German and Chinese terminal blocks. First, what you can see immediately in the store during an external inspection of the product:

- The flags (or levers) on the Chinese terminal block are of a darker (or even dirty) orange hue, in German they are brighter and lighter.

- On the end of the original product there is a branded inscription "Wago", nothing is written on the Chinese clip.

- On the reverse side of the terminal block, the German manufacturer places a schematic instruction for use and the dimensions of the wire stripping. In the Chinese copy, the reverse side is blank, nothing is written or drawn.

- On the side of the German terminal block, two values are indicated - the operating voltage and the rated throughput current. In Chinese - only the voltage is written 250 V.

If you look at the inside of both instances, then at first glance everything will seem the same. But if you pull out the contact strip, you will see that the Chinese manufacturer has it twice as thin as the German one. In the original terminal strip, the contact strip is not magnetised, in the Chinese one it is attracted to the magnet.

For details on fakes, see here:

We tried to convey the basic information on the Wago self-clamping terminal blocks.There are enough places in the home electrical network for their use. Therefore, if you just cannot give up the old old-fashioned method of twisting, we advise you to think about more advanced technologies. It's so easy, fast and, most importantly, inexpensive.