How to twist wires correctly

We are not going to prove to you that twisting wires is a good way to connect. Yes, it can be made with high quality and insulated. It is also great as a temporary option. But according to the rules of electrical installations (PUE), in order to connect a wire or cable, ordinary twists are not recommended. Nevertheless, we will have a conversation about it, and very detailed. Firstly, because, contrary to the PUE, most of the connections are performed by this old "old-fashioned" method. Secondly, because correct twisting is the main stage of the most reliable ways of connecting wires - welding and rations.

Content

What is a good twist for?

Imagine that two wires to be connected are twisted together just like. Those familiar with electrical engineering know that a transition resistance occurs at the point of contact between two conductors. Its value depends on two factors:

- surface area at the point of contact;

- the presence of an oxide film on the veins.

To perform twisting, the core is exposed, the metal interacts with atmospheric oxygen, as a result of which the surface of the conductor is covered with an oxide film, which has a decent value of resistivity.

Accordingly, if the twisting is performed poorly, the contact resistance increases, which in turn will cause heating when an electric current passes through the junction. As a result, the place of twisting can heat up so that the electrical wiring will catch fire. Surely everyone had to hear the phrase in life that the fire was due to a power failure.

To prevent this from happening, the contact connection of the wires must be as strong, reliable and safe as possible. That is, the twisting must be performed so well that the transition resistance is stable and does not change over time.

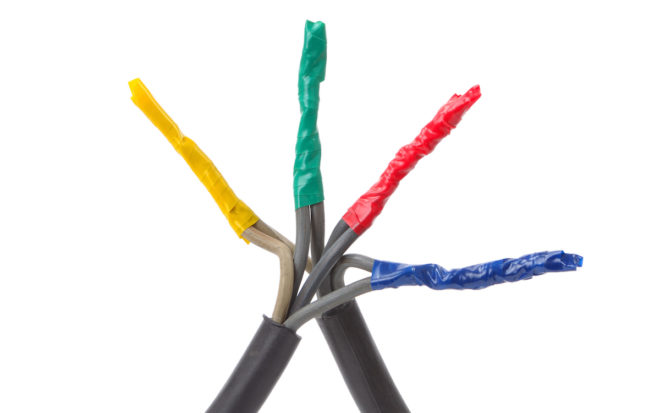

Preparing wires for twisting

To get a good twist, you need to follow these steps exactly:

- Strip the conductors to be connected from insulation, while not allowing damage to the metal surfaces of the conductors.

- Soak a clean cloth in white spirit or acetone and wipe off any dirt from the exposed cores.

- Now use sandpaper to smooth the veins to a metallic sheen.

And then you can start twisting.

Stranded wires

The twisting of stranded electrical wires can be done in different ways.

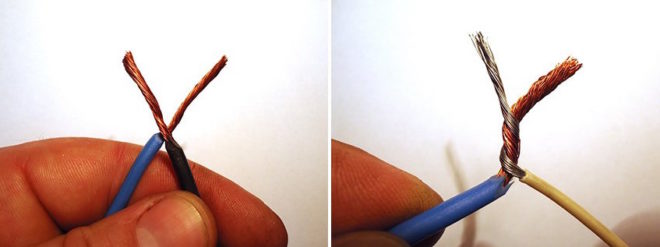

Parallel twisting

The simplest method is parallel twisting, when both stripped wires are crossed crosswise overlapping each other at the stripping point and twisted at the same time. Such a connection provides a reliable contact, but it will not withstand the applied tensile force and vibration.

This method is best used for copper wires, when one of them is monolithic and the other is stranded. A monolithic wire must be stripped of insulation a little more than a stranded one. After twisting, an additional bend is made from the remaining monolithic copper tail towards the twist, due to this, the connection is more reliable.This method is also suitable for twisting aluminum conductors with different cross-sections.

The advantage of parallel twisting is that it can be used to connect more than two wires simultaneously.

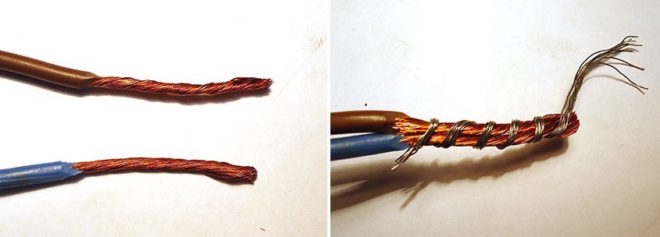

Sequential twisting

With the sequential method, each wire to be connected is wound onto another. The reliability and contact of such a connection will be optimal, but this twist can be used only for two wires, no more.

Fold the stripped veins cross-to-cross on top of each other approximately in the middle of the exposed area and begin to twist. One wire goes around the other wire, in the same way wind the second wire around the first.

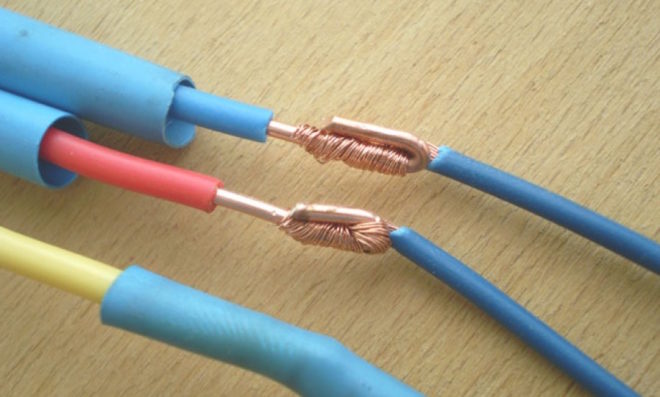

Bandage twist

Stranded wires can be connected to each other by the method of bandage twisting. In this case, the wires to be connected are stripped to the same length and applied parallel to each other. In this position, they are fixed with a third wire, which is tightly wound onto the bare surface of the connected wires.

Please note that with the help of such a twist, you can connect rigid stranded wires, but you must definitely use a soft (flexible) wire as a fixing one. The tighter you wind the fixing wire, the more reliable the contact connection will be.

More than two conductors can be connected by means of a tie strand.

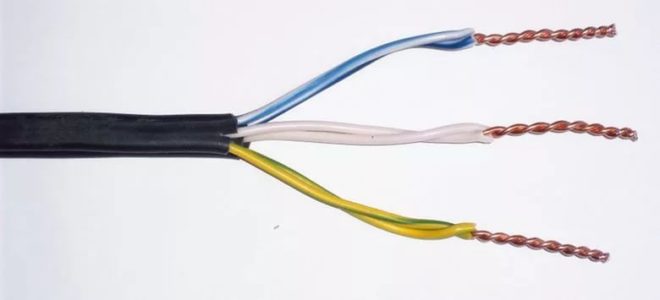

Single core wires

All the above methods of twisting stranded wires can be used for single-core wires. But it's best to use a parallel connection in this case.

Remember the most important thing, before connecting single-core wires, the insulating layer on them should be stripped only along the conductor at an angle. This is especially true for aluminum conductors. If you run the knife at a 90 degree angle around the conductor, the insulation will of course be removed. But in further work, with the slightest movements in the place of the incision, the conductor will eventually go to a break and, ultimately, the vein will break.

Strip the insulation layer on the wires to be connected 3-4 cm. Lay the wires on top of each other at an angle of 45 degrees, but not in the place of the bare wires, but 1.5-2 cm higher from the place where the insulation was cut. Hold this place with your left hand, and start twisting both wires with your right hand. First, they will be twisted together with the insulating layer, then the connection of purely bare cores will go.

No matter how strong your hands are, at the end, be sure to finish twisting with pliers, especially this again applies to aluminum wires.

If you need to perform a large number of twists, you can use a screwdriver with a homemade device, as shown in the video below:

Twist Insulation Methods

Twisting the wires is half the battle; it is very important to insulate this place with high quality. There are three ways to insulate a made electrical unit: using insulating tape, heat-shrinkable tubing and PPE caps. Let's consider each of them in more detail.

Insulating tape

Insulating tape is a special material, the main purpose of which is to insulate the junction of electrical cables and wires. Whatever modern technologies appear, it is hardly possible to find an electrician who does not have a roll of electrical tape in his pocket. It is the most common and inexpensive insulating material.

There are many varieties of it.Tapes are made on the basis of mica and fiberglass, polyester and epoxy films, acetate fabric and paper. We recommend using PVC tape (polyvinyl chloride is used) to isolate the twist in the household electrical network. To make it, take a polyvinyl chloride film and apply glue on top. The quality of the insulating tape itself depends on the quality of these two components, and, accordingly, the reliability of the insulated junction.

The best is considered electrical tape, for the manufacture of which they use rubber-based glue and PVC film of class A. This material has such positive qualities as:

- High adhesion (adhesion of dissimilar surfaces).

- Increased elasticity (perfectly stretches and glues).

So be sure to consider this when buying duct tape.

The insulating tape should be wrapped around the twisted section in at least two layers. Start winding 2 to 3 cm above the bare strand, with the tape overlapping the wire insulation. This will allow achieving maximum tightness and insulating reliability, and will protect the contact connection from moisture ingress. Then wind a little at an angle, moving towards the end of the twist. When you reach the end, bend the tape around the tip of the twist and continue winding now in the opposite direction. When you reach the place where you started winding, cut the insulating tape with a knife. For efficiency, you can repeat the same thing again and make the insulation in four layers.

It is recommended to use this tape for insulating twists installed in dry rooms.

Thermal tube

A heat-shrinkable tube (abbreviated as HERE) is made of thermopolymer materials, which tend to change their geometric shape and size (shrink or expand) under the influence of hot air, water or elevated temperature.

The main advantage of thermotubes is that they can be put on objects with a complex profile, which is exactly what the twisting of wires has. The heat-shrinkable tubing provides excellent electrical insulation and protects against mechanical damage. Tubes are available in different diameters. The material from which they are made is non-combustion and non-toxic.

Industrial hair dryers are used to heat the tubes. This tool is not cheap and buying it just to insulate the splicing of wires is not economically viable. Therefore, at home, they often use an ordinary hair dryer or a lighter.

It is important to remember that with this method of insulation, the heat-shrinkable tube must be put on one wire to be connected in advance (before twisting).

Cut the tube off with a margin, when it is put on the bare area, it should step over the insulating layer of the conductor by at least 1 cm.

When the twisted connection of the electrical wires is complete, pull the tube over this place. Direct a heat stream of a hair dryer or a lighter flame at it, under the action of hot air the tube will instantly decrease in size and tightly squeeze the insulated area. Safe, fast and inexpensive way.

Note that the connected wires, which are insulated with a thermal tube, can be used for buried or submerged applications. This insulating material is recommended for use outdoors, in saunas and bathrooms, as it will reliably protect the twist from moisture.

How to choose to use a heat shrink tubing is shown in this video:

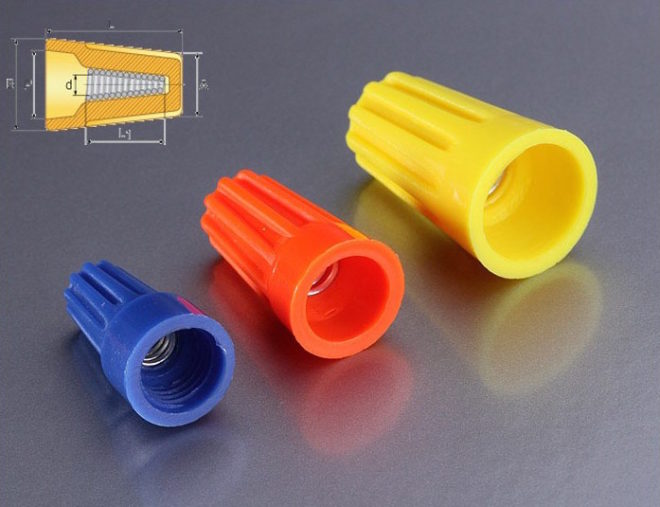

PPE caps

When installing wiring in an apartment or house, PPE caps (connecting insulating clamp) can be used as insulation of the connection points.

In this case, it is enough to make only high-quality twisting, without soldering. The tip must be cut and put on with the effort of PPE, the crimp springs inside the cap will move apart and tightly grip the joint to be connected.For a better fit to the joint surface, twist the cap clockwise.

Now you know how to properly twist the wires, what material is better to choose for insulating the junction. It is clear from the article that it is not at all necessary to be a professional electrician to perform twisting; such work is within the power of anyone who knows how to hold pliers in their hands. Just remember that twisting is just an important step to be completed by welding or brazing.