How easy it is to make conductive adhesive with your own hands

In the event of a breakdown of a household electrical appliance, it is not necessary to immediately hand it over for repair, because often a malfunction may be a loss of contact between the tracks on the board, and to eliminate this problem, it is enough to have conductive glue on hand. You can buy a ready-made composition in a network of stores without problems, the choice of assortment is wide enough: Kontaktol, Elecont, Elast varnish, etc., but for radio amateurs and those who often do repairs on their own, it is preferable to make your own required composition. To do this, it is enough to have a minimum of necessary components and know how to make conductive glue with your own hands.

Content

Features and properties of conductive adhesives

The basis of such an adhesive is the presence of certain constituent components that can provide the required level of electricity transmission. These include ordinary graphite, nickel powder, polymers, powder silver - fine powder of any of the conductive metals will do.

The basis of such an adhesive is the presence of certain constituent components that can provide the required level of electricity transmission. These include ordinary graphite, nickel powder, polymers, powder silver - fine powder of any of the conductive metals will do.

The adhesive mixture must be flexible and, at the same time, have a low specific resistance. The elasticity will ensure that the glue is applied to a spot and will not spread over the surface. In this matter, the main thing is to maintain the required ratio between powder electrically conductive fillers and polymer binders. A large number of additives capable of conducting current can lead to a decrease in the qualities of adhesion to various surfaces, which will affect the reliability and strength of contacts.

The next important feature for work will be the time required for the prepared mixture to dry. The faster the glue dries, the better and more convenient it is for the master. For this, in the self-production of the adhesive mixture, any ready-made quick-drying glue or conductive varnish is used. Due to the fact that microcircuits heat up during operation, the glue must be heat-resistant and necessarily safe for the working master and others.

Self-made graphite dust adhesive

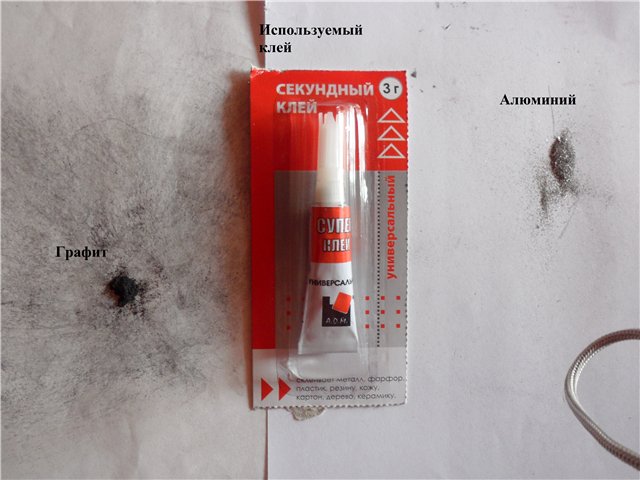

One of the most accessible and widespread methods is to use graphite dust as a conductor. To prepare a conductive glue, you need only two components - graphite itself and a binder in the form of any quick-drying glue or varnish. It is not difficult to prepare graphite powder; the core of a construction or ordinary pencil is perfect for this purpose. The lead, using a clerical knife, must be removed and ground into a fine powder.

When using ready-made glue, the lower part of the tube is neatly unfolded and graphite powder can be added to the resulting opening in a one to one ratio. Stir the mixture well using a toothpick or any other convenient object. After that, the foil of the lower part of the tube is wrapped back and the self-made electrically conductive compound is ready for use as intended. The advantage of a composition prepared on a graphite base will be a quick drying time.

In addition to a pencil, worn-out copper-graphite brushes or a carbon rod from a salt battery can be used to prepare graphite powder. You can grind graphite with fine sandpaper or a file. It is also important to remember that when using varnish as a binder, the reliability of the connection will be lower than when using a ready-made adhesive.With the addition of copper powder to the composition, electrical conductivity is significantly increased.

The scope of application of a self-prepared electrically conductive composition is quite extensive. For example, universal conductive glue restores the tracks of the remote control board, computer keyboard - wherever it is not possible to use a soldering iron. Often used by motorists, when it is necessary to restore the rear window heating contacts.

How to make electrically conductive glue from a pencil lead is shown in this video:

Additional recipes

Graphite dust is not the only component that can be used to make conductive adhesives. There are several more complex mixtures with better electrical conductivity or adhesive properties:

- A mixture of silver powder (130 g) and graphite (12 g) are conductive components, and nitrocellulose (8 g), acetone (50 g) and rosin (3 g) act as binders. In the listed order, everything is mixed in a mortar until smooth and the glue is ready. If the glue thickens, then it must be diluted with acetone. This composition is more calculated as conductive - you should not expect that it will hold any parts like glue.

- Graphite (30 g) and silver (70 g) powder, acetone (70 ml) and vinyl chloride-vinyl acetate (60 g) - after mixing, become a syrupy conductive liquid with adhesive properties. Store in an airtight container so that acetone does not erode. They also dilute the mixture if it thickens.

- The powder from the graphite rod of the finger-type battery and the chainlak are mixed until a creamy mixture is obtained.

What conclusions

Of course, there are other recipes for homemade glue, and only the simplest and most common are considered above. Whatever recipe is used, the main thing is that the glue you cooked yourself, or the glue purchased in the store, should have the lowest possible resistivity. And like any other, such an adhesive must provide a strong, reliable and durable connection.