How to quickly and correctly strip the wire from insulation

In production and in everyday life, questions often arise on how to strip the wire. Unfortunately, many craftsmen, performing this work, make a number of technical errors, which further impairs the operation of electrical systems.

Wire stripping is needed in a variety of cases:

- if necessary, connect the wires to increase the length of the conductor;

- when performing wiring inside a residential building or any other building;

- when connecting lighting devices;

- when connecting equipment using electrical devices (machines, stands, conveyors, tools and other equipment);

- when installing switches and sockets;

- when installing special control and regulatory equipment in switchboards, etc.

Before you start stripping wires, you need to know the features of their structure and insulation. Then it will become clear how to proceed in each specific case.

Content

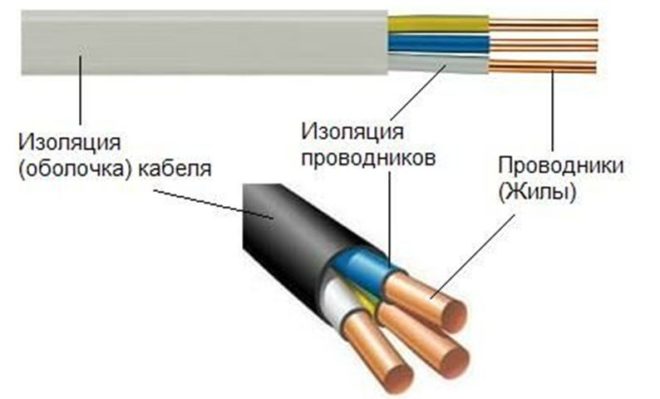

Features of the structure of electrical wires

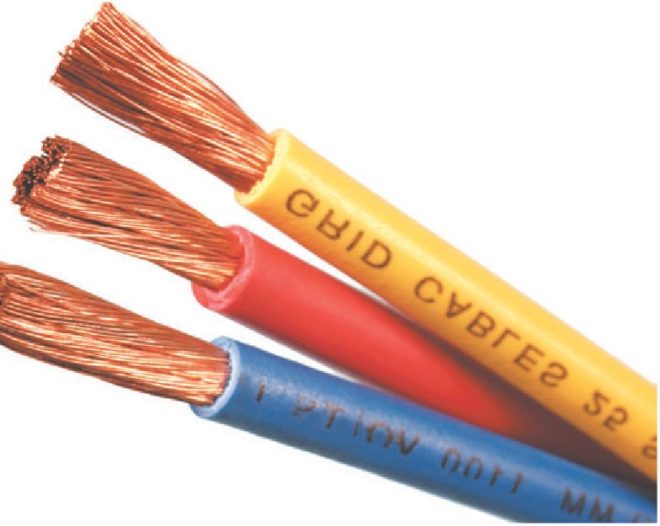

Electric wires are manufactured in two versions:

- single-core - have a single core, enclosed in insulation;

- stranded ones are twisted conductors enclosed in general insulation.

For single-core wires, the cross-section is formed only due to one core. Cross-sectional area Is a characteristic in square millimeters that is used when choosing depending on the magnitude of the current. In stranded wires, the cross-sectional area is set by the total set of all available cross-sections of the conductors. For elasticity, a nylon thread is often added inside - this small addition improves the performance of the cable.

Insulation can be single or double. It is made from various insulating materials:

- plastics are polymeric materials based on organic compounds; thermoplastics are more often used - they soften when heated. They can mix with each other, uniting into a single whole. These plastics support combustion, while emitting various toxic gases;

- plastics that harden when heated are called thermosetting. Insulation is made of them only for special applications, when increased requirements are imposed on it;

- different types of natural or artificial rubber (rubber), hardening when heated, as well as supporting combustion;

- insulation on a fabric basis, some types of fabric can withstand quite high heating (up to 400 ° C), while maintaining insulating properties;

- shielding braid, which serves to protect wires from electromagnetic influences, it does not insulate, but creates additional mechanical protection against damage;

- "Armor" braid is used to protect cables from damage.

Depending on the type of insulation used, we remove it using different tools.

How to properly strip wires from insulation

Wire stripping requirements:

- the stripped (bare) part must be completely hidden inside the connection;

- from the surface of the core, insulation must be removed from all sides.

Home craftsmen mistakes:

- Home craftsmen often leave exposed wire exposed. In case of accidental contact, a person can close these places and receive an electric shock;

- If fragments of insulation remain on the veins, then its compression inside may be insufficient for reliable fastening. In case of vibration, for example, the electrical wiring in a car, the connection will loosen, the wire will come out of the terminals of the device, and a short circuit with ground will occur. The vehicle may catch fire.

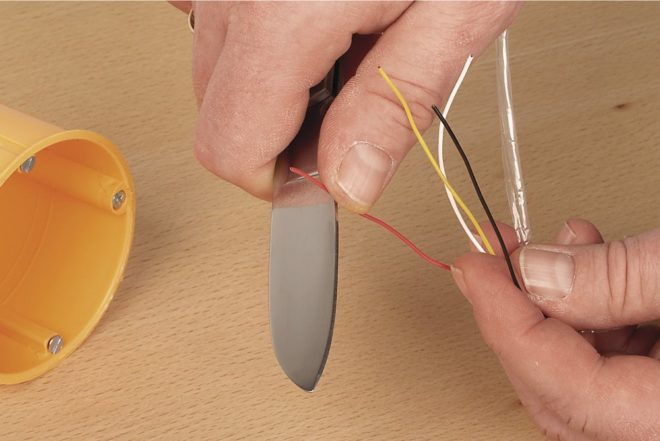

Cutting insulation from wires with a knife

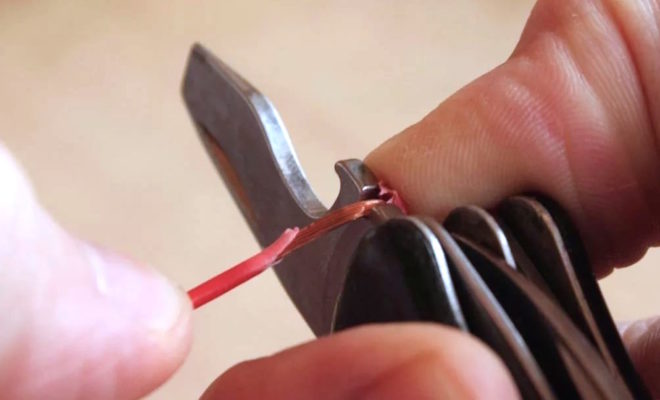

The knife is the most widely used tool and is therefore the most commonly used. It is necessary to expose not only individual conductors, but also cables in which there are several wires. Therefore, at the first stage, the cable is cut along the length, the wires are laid in different directions, and then the outer sheath is cut across. Repeat this operation if necessary.

To strip the insulation off the wire, place the blade almost parallel to the wire and then cut off a thin layer of insulation. In the future, slightly turning the conductor, cut off the remaining thin layers. Turning completely through 360 °, achieve a complete cut of the coating. These steps are easy to perform if you need to strip thick enough wires.

When stripping thin wires with a knife, only cut through the insulation layer.

After circular cutting to a shallow depth, it is easy to strip the wires from the insulation, it is removed from the surface in the form of a tube.

Thick conductors of cables for high power supply are cleaned by cutting the plastic across and then along. Then the protective shell is easily removed.

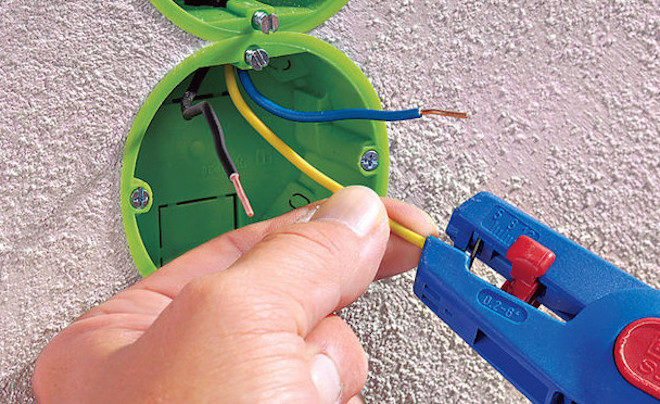

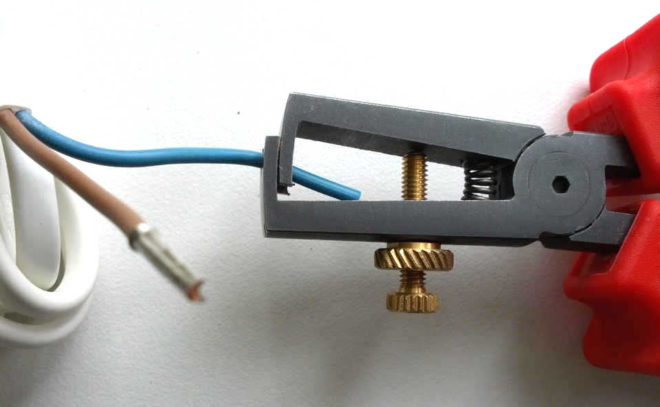

Removing insulation with special tools

Professionals have a fairly extensive range of insulation stripping aids. Their principle of operation is as follows:

- A suitable stream is selected on the instrument to expose the required conductor.

- The wire is installed in this stream.

- Squeeze the handles.

- First, the wire is squeezed, and then the scraper removes the insulating layer.

The entire procedure takes no more than one second of time. But such devices have a rather high price, so they are purchased by professionals who have to perform a large amount of such work during a work shift.

For more information about the stripping tool (strippers), see this video:

Some home craftsmen decide how to remove the insulation from the wire by making a simple device on their own. To do this, use a strip of metal (preferably a piece of cloth from a hacksaw). An angled slot is made on it to match the size of the wire. The inner surface of this slot is sharpened to obtain sharp edges.

For information on how to make a device for stripping wire insulation, see this video:

If it is necessary to remove the insulation from the wires, each conductor is clamped in the corner slot to the required amount, and then pulled with effort. As a result, the plastic can be easily removed from the metal.

On sale sometimes you can find special pliers in which there are similar slots. There are usually several of them to strip wires of different diameters from insulation. To perform the operation, the conductor is clamped in the stream, and then simply pulled in the desired direction.

There are special combs for one- and two-sided insulation stripping. They are inexpensive, take up little space, and cut off the insulation quite easily.

Some craftsmen use side cutters. They also crimp the conductor on both sides. By extending the wire, the plastic insulation can be quickly removed.

Difficult stripping options

Certain difficulties arise when removing fabric insulation. The thread is wound quite tightly; it is difficult to cut it with a knife. They do things differently here.Using sandpaper, clean the desired area from one side. The rest of the thread comes off easily.

PELSHO wires are often used by radio amateurs. They use filament winding. So it is removed using fine-grain sandpaper. The conductor is placed on a wooden support, and then with several movements, pressing the abrasive to the support, the thread is destroyed from one side. Then it is easy to remove it.

If it is necessary to strip the shielded wire, cut the outer sheath, and then remove it. Next, the braiding is unwound, freeing the insulation in the required place. Only then is the insulation removed from the middle conductor.

In some cases, you can remove plastic from metal using heated surfaces. This is sometimes done by radio amateurs to remove the protection with a soldering iron.

Sometimes the cover is removed by burning it in a fire. This method is extremely dangerous. It is prohibited to use it. Harmful gases are released, the insulating coating is removed unevenly, part of it does not fulfill its functions after overheating.

Any home craftsman will be able to remove the insulation from the wire using a sharpened knife. It is not difficult to make the simplest tools for this job. Purchased devices will allow you to do this work quickly and efficiently.