How to find out the cross section of the wire

Overhaul is an inevitable event that has to be done in any residential or utility room. In addition to external finishing work, it provides for the replacement of all communications, including electrical wiring, which must be selected and bought. Unfortunately, the information indicated on the tag or the cable itself often does not correspond to reality, albeit on legal grounds (the permissible error is prescribed in GOSTs), therefore, in order to protect yourself from buying a low-quality cable, you need to know how to determine the wire cross-section.

Content

Why do I need to specify the cable cross-sections

On most wires and cables, the manufacturer is obliged to apply markings indicating their type, number of conductive cores and their cross-section. If the wire is marked as 3x2.5, it means that the cross-section of the wire is 2.5 mm² in diameter. Actual values may differ from the indicated ones by about 30%, because some types of wiring (in particular, PUNP) are made according to outdated norms that allow for an error of the indicated number of percent and generally it appears in a smaller direction. As a result, if you use a cable with a smaller cross-section than the calculated one, then the effect for the wire will be about the same if a thin polyethylene hose were connected to a fire hydrant. This can lead to dangerous consequences: overheating of electrical wiring, melting of insulation, changes in metal properties. Therefore, before making a purchase, it is imperative to check that the cross-sectional area of the conductor does not differ from that declared by the manufacturer.

Ways to find out the real wire diameter

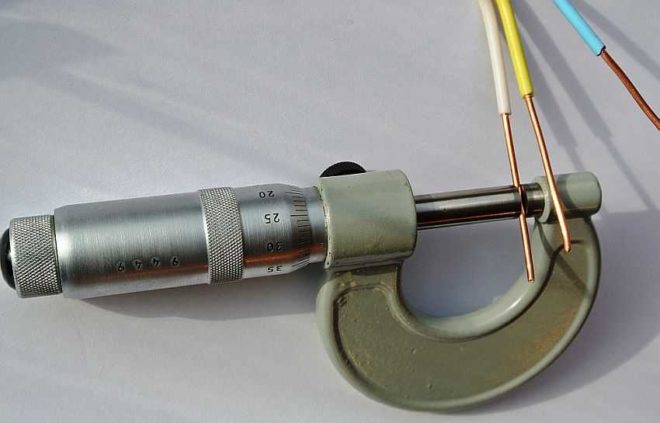

The easiest and most accurate method to measure the diameter of a wire strand is to use special tools such as a vernier caliper or micrometer (electronic or mechanical). For the measurement to be accurate, the measured wire must be cleaned of insulation so that the tool does not cling to it. You also need to inspect the end of the wire so that it is free of kinks - sometimes they appear if the vein is cut by blunt nippers. When the diameter is measured, you can begin to calculate the cross-sectional area of the wire core.

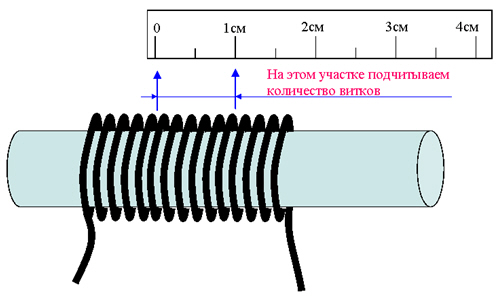

In the case when there is no precise measuring tool at hand, there is another way to find out the cross section - it will need a screwdriver (pencil or any tube) and a measuring ruler. You will also have to buy at least one meter of wire (50 cm will be enough, if only that amount is sold) and remove the insulation from it. Further, the wire is wound tightly, without gaps, on the tip of a screwdriver and the length of the wound section is measured with a ruler. The resulting winding width is divided by the number of turns and the result will be the desired wire diameter, along which you can already search for the cross section.

How to take measurements is shown in detail in this video:

What formulas should be used

What is a wire cross-section is known from the basics of geometry or drawing - it is the intersection of a volumetric figure with an imaginary plane. From the points of their contact, a flat figure is formed, the area of which is calculated by suitable formulas. The core of the wire is most often cylindrical and gives a circle in cross-section, respectively, the cross-section of the conductor can be calculated by the formula:

S = ϖ R²

R is the radius of the circle, equal to half the diameter;

ϖ = 3.14

There are wires with flat cores, but they are few and the cross-sectional area on them is much easier to find - just multiply the sides.

To get a more accurate result, you need to keep in mind:

- The more turns (there should be at least 15) screw on the screwdriver, the more accurate the result will be;

- There should be no distance between the turns, because of the gap, the error will be higher;

- It is necessary to take several measurements, each time changing its beginning. The more there are, the higher the accuracy of the calculations.

The disadvantage of this method is that conductors of small thickness can be used for measurements, it will be difficult to wind a thick cable.

Determine the cross-section of the wire using the table

Using formulas does not give a guaranteed result, and as luck would have it they are forgotten at the right time. Therefore, it is better to determine the cross section according to the table, which summarizes the calculation results. If it turned out to measure the diameter of the core, then the cross-sectional area of the wire can be viewed in the corresponding column of the table:

If you need to find the total diameter of the stranded conductor of the cable, you will have to separately calculate the diameter of each wiring, and add the obtained values. Then everything is done in the same way as with a single-wire core - the result is found according to a formula or table.

When measuring the cross-section of a wire, its core is thoroughly cleaned of insulation, since it is possible that its thickness will be greater than the standard. If there are doubts about the accuracy of the calculations for some reason, then it is better to choose cables or wires with a power reserve.

To approximately find out the cross-section of the wire that will be purchased, it is necessary to add up the power of the electrical equipment that will be connected to it. The power consumption must be indicated in the passport of the device. Based on the known power, the total current that will flow through the conductor is calculated, and based on it, the cross section is already selected.

Tips for choosing a wire size

The cross section of the conductor is not all you need to pay attention to. The material from which it is made is of no small importance. A core made of copper or aluminum has a certain color and if it is in doubt, then probably in order to save money, the manufacturer uses a metal alloy here. This can lead to dangerous consequences, since the current conductivity will be less than that of the declared metals.

The wire cross-section is determined only by the diameter of the current-carrying conductor. Some buyers mistakenly try to calculate the cross-section for the total diameter (core + insulation), subtracting the estimated thickness of the insulation from the result. In no case should this be done, since the measurement error will be excessively high. In addition, in order to save metal, the insulation itself can be made thicker by the manufacturer, and in appearance the product seems quite normal.

Section according to GOST or TU

A wide range of electrical products contributes to the rapid solution of problems that are associated with electrical work. The quality of these products plays a very important role and all products must meet the requirements of GOST.

As a result, the market is oversaturated with low-quality and cheap goods that need to be double-checked before buying.

If cables of suitable cost available in retail outlets do not correspond to the declared characteristics, the only thing that can be done is to purchase a wire with a cross-sectional margin. Power reserve will never negatively affect the quality of wiring. It will also be useful to pay attention to products from manufacturers who value their names - although they are more expensive, they are a guarantee of quality, and replacement of wiring is done not so often in order to save on it.