Choosing a cable for an electric stove and a hob by type and section

The operational safety of a classic, induction, halogen, glass-ceramic electric stove depends on a competent connection to the electrical network. It is important to choose the right:

- brand and cross-section of power cables, wires;

- power outlet, plug;

- introductory machine and RCD (difavtomat);

- diagram and method of connection to the mains.

In addition, it is necessary to allocate a separate line for supplying a cable or wire from the electrical panel to the connected product and carry out grounding. The combination of lighting and outlet lines with the power supply of the electric stove is not allowed. This is directly stated in the PUE.

For the correct solution to the issue of installation and connection, it is necessary to study the passport for the installed product, as well as the manufacturer's recommendations for installation and maintenance. Usually, the necessary information is indicated in the instruction manual, which, together with the passport, is attached to each product by a bona fide manufacturer. In addition, the connection of the electric stove cable must be carried out in accordance with the instructions of the PUE and other regulatory and technical documentation regarding the installation and operation of energy-intensive products. The same rules must be followed for the oven and hob.

Content

Features of the choice of cable for the plate

The manufacturer does not always complete an electric stove or other kitchen device of a similar type with wires for connection. And then there is a need to purchase a wire. What brand, section and with what core material to choose? The cable for the hob, electric stove, oven is selected taking into account the power of the product and the phase of the connection. The first parameter is indicated in the passport data, the second depends on the number of cores of the cable supplied to the stove (three-core or five-core), and this already depends on the power supply (single or three-phase). The wire or cable must be with copper conductors. According to the requirements of the PUE, it is not allowed to connect cables with aluminum conductors to energy-intensive products.

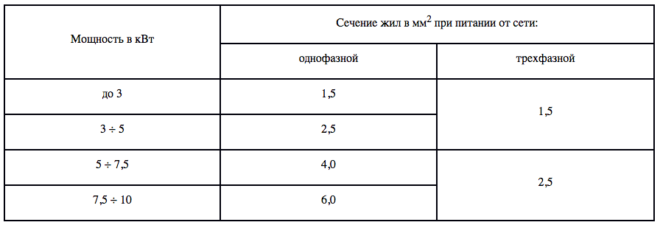

The cross-section of the cable cores is selected depending on the power of the energy-intensive product (electric stove, hob, oven) and the type of power supply according to the table:

The power supply of the plate from a single-phase network means that the cable must have 3 cores - phase, zero and ground, from a three-phase 5 cores - there are 3 phase cores, zero and ground.

Now you need to decide on the brand of wire. Years of experience in the operation of products indicates that the best cables for connecting an electric stove are PVS and KG brands.

Information about wire and cable brands PVS and KG

The abbreviation PVS stands for vinyl connecting wire... Used to connect electrical devices and devices to the mains. It is a product with conductive copper conductors (from 2 to 5), protected by insulation (each conductor) and enclosed in a common white insulating sheath.The conventional designation of the wire, in addition to the abbreviation PVS, includes the number of cores and the diameter of each core, for example, the designation PVA 3x4 is deciphered as follows: vinyl connecting wire with three conductive cores with a diameter of 4 mm. PVA can withstand a voltage of 450 V. The insulation material does not support combustion, which classifies the wire as a standard product for fire resistance. Has high strength and bending resistance. The wire can be used in damp and unheated rooms. Depending on the operating conditions, it lasts from 6 to 10 years. The low price makes it popular when connecting electric stoves of different capacities.

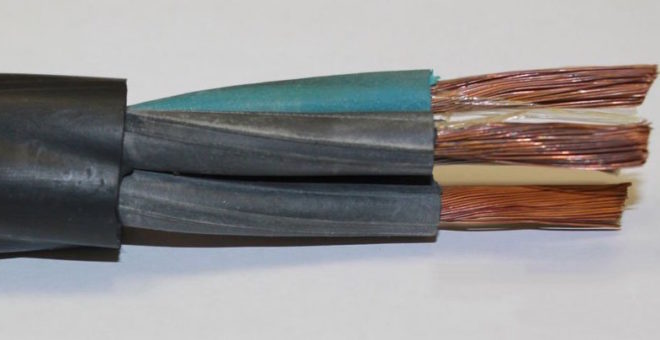

The abbreviation KG stands for flexible cable. The role of the casing is played by a special rubber. Inside the cable there are also tinned copper conductors in a rubber sheath, and between them there is a protective film, the purpose of which is to prevent sticking as a result of heating during operation. Produced by manufacturers with the number of cores from 1 to 5. The cross-section of the core determines the power that the cable can withstand. The cable can be operated within a fairly wide range - from minus 40 to 50 0C to rooms with high humidity with a voltage of up to 660 V.

The symbol consists of the abbreviation KG, the number of phase and grounding conductors, indicating their cross section. For example, the designation KG 3x5 + 1x4 is deciphered as follows: 3 phase conductors with a cross section of 5.0 mm2 and 1 grounding section 4 mm2.

Regardless of which brand is selected for connecting an electric kitchen device, a wire or cable must be purchased with a margin of length so that the product can be moved. PVA and KG are easy to fit due to their increased flexibility and are simply connected to the plate. When connected to the contacts of the product, the ends of the wire or cable must be stripped from oxidation, tinned and then they can be fixed as follows:

- shaping and clamping with washers;

- squeezing into special sleeves;

- through handpieces type TML.

Connection features

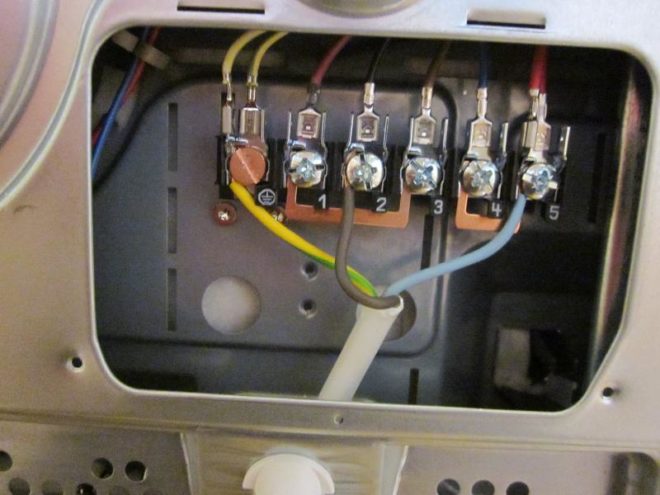

Modern electrical devices are available in a large assortment and are endowed with different functions. The connection to the power source is carried out according to a schematic diagram that allows you to connect the stove to a 220 V or 380 V network. The necessary power for a specific network is provided by installing special jumpers. The junction box on the rear wall of the product has an image of such a diagram. The color of the core insulation helps to make the correct connection. A wire with insulation in black or brown is connected to the phase contact, blue to zero, yellow-green to ground. According to the international designation, near such terminals there are respectively the letters L, N and the inverted designation of the letter T. After the wire or cable is securely connected to the installed product, it remains only to connect it to the electrical panel. Now, using a tester, you need to check the correct connection. The work is considered complete and the product can be used if the manufacturer has equipped it with a socket to connect the electric stove. And if it is not there, then you need to purchase a Euro plug with three pins for 25 ÷ 32 A and a PVA wire 3 x 2.5 in an amount of at least 2 m and make the necessary connecting device. The tester checks the correctness of the connection for lack of short. (short circuit) between each wire of the cable and on the plug in the absence of contact between ground and phase, while all switches on the product must be inoperative. The same check is carried out with different operating modes of the switches. Resistance readings between 4 and 10 ohms are considered normal when the mode is set to 100 ohms.

In any case, the block for connecting the supply wire or cable contains six terminal clamps and there is always a schematic diagram in the operating documents or on the stove itself, with which you can, having figured it out, connect the cable of the oven, electric stove or hob yourself if you have the necessary tool and measuring device (tester).

How the electric stove is connected is shown in detail in this video:

To protect the wire or cable, a differential automatic or a circuit breaker with characteristic C and RCD is installed in the apartment or house panel.

Grounding the electric cooker

The electric stove must be grounded. All work in homes is divided into 2 categories:

- the presence of a common ground loop;

- lack of a grounding loop.

In the first case, you will need a copper flexible wire with a cross section of at least 2.5 mm2, which must be laid from the electrical panel and connected to the plate body. In the second case, installing an RCD, performing zeroing (using a protective zero conductor), or both methods together will help.

Where there is no centralized gas supply, an electric stove is a necessary kitchen device and its operation and period of use depend on how it is connected. When choosing a cable or wire, you need to choose the right brand, wire cross-section and its quantity, and also pay attention to the manufacturer of this product. And do not forget that electric current is a source of increased danger, leading to undesirable consequences. Therefore, it is better to entrust the installation of an electric stove to specialists who know all the intricacies of such a connection, and are also well versed in the necessary materials, accessories, fixtures and know how to use a control and measuring device.