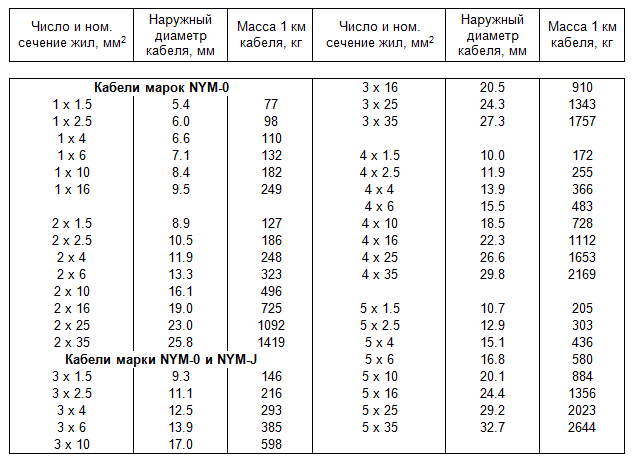

NYM Cable Specifications

For most electrical work, NYM cable is recommended for use, the technical characteristics of which correspond to European standards. To use it, there are some restrictions that you need to know before buying, so it is better to see a description of all operational and technical characteristics in advance.

Content

NYM cable: performance and specifications

It is a versatile conductor used for socket and lighting installations. Technical characteristics allow it to be equally used in production and when laying household wiring, which determines the high demand for products with such markings. The abbreviation in the name of the cable reflects the main information regarding its application:

- N - this letter shows the compliance of the products with the main European standards.

- Y - wire insulation is made of PVC.

- M - means no special restrictions on use, i.e. this wire is not intended for any one type of electrical work.

The standard by which it is manufactured was developed in Germany, but its main provisions quickly spread in European countries and the CIS countries, where it is manufactured at many factories, albeit according to slightly modified specifications.

Design features of NYM cable

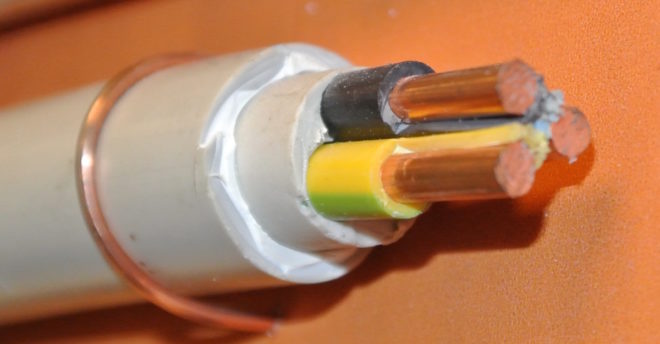

For the manufacture of cores, a copper conductor is used. If its cross-section is from 1 to 10 mm², then the wire is single, and for cables from 16 to 35 mm², conductors are made twisted from several conductors.

Insulation and internal filling slightly differ from the number of cable cores. When there are 4-5 of them, then there is a PVC cord in the center of the wire, which prevents the displacement of the conductors. If there are 2-3 wires, then there is no need for it. In all cases, NYM wire has three layers of insulation:

- polyvinyl chloride separately on each core;

- chalk-containing rubber is pressed into the empty space between the wires;

- the outside is covered with PVC compound.

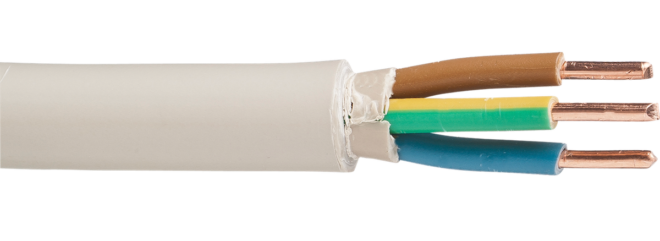

These wires are available in two versions, differing in the color of the core insulation - for use in electrical circuits with and without grounding - they differ from each other by using the letters J or O on the external insulation.

- In the first case, the cable is marked as NYM-J, which indicates the presence of at least three cores in it, one of which is yellow-green.

- In the second case, the NYM-O marking is used, showing that there is no yellow-green wire, but there is a blue core for the neutral conductor.

The number of cores in NYM cables can be from two to five, and the following colors are used in their colors: black, blue (NYM-O), yellow green (NYM-J), brown.

Main characteristics

For NYM cable, the main technical characteristics determine the scope of use:

- Maximum voltage up to 660 Volts.

- The number of cores is 2-5.

- The permitted temperature of use (at which there are no noticeable deviations in the properties of the cable) is from -50 to +50 C °. It can withstand prolonged heating up to +70.

- The permitted installation temperature is higher than -5 C °. If the laying of the wire must be carried out at a temperature below the specified one, then heating of the place of laying and of the wire itself is required - otherwise, damage to the sheath is inevitable.

- High elasticity - bending radius during installation from four outer diameters.

- The maximum humidity at which the wire can be is 98% (you cannot lay it under water).

- Restrictions on use - it is forbidden to use the NUM cable for laying underground, and when using it outdoors, it must be hidden in a corrugation, since PVC insulation is destroyed over time from exposure to ultraviolet radiation.

- Factory packing - bays of 50 or 100 meters, reels of 500 meters.

- The estimated period of operation under normal conditions is 30 years.

- The manufacturer's warranty period is 5 years.

For more information on the characteristics of the cable, see this video:

and here you can see the tests of the flammability of the NYM cable in comparison with the VVGng-LS cable:

and comparison of cables from different manufacturers:

Differences in technical characteristics: VDE vs TU

Specifications may vary slightly depending on the manufacturer. Wires made in German factories are made according to the VDE standard and are approximately the same in all cases. In the CIS countries, manufacturers are guided by local technical specifications (TU), therefore, not only cable properties are different, but also its labeling.

Local manufacturers can save money by at least using filler, which is pressed into the space between the veins. In original cables, this is chalk-filled rubber that does not support combustion, and in domestic cables, other material can also be used. As a result, original cables can be used even in the presence of minor damage, and in this case it is better not to use domestic ones.

It must be borne in mind that the manufacture of electrical wires in artisanal conditions is a rather thankless task - whatever one may say, but for the wire you need copper or aluminum, since there is nothing to save on here. As a result, all products of this kind are usually certified and if you look closely at the labeling, it is quite easy to distinguish the original from local products, at least by marking - the letters VDE and NYM are necessarily affixed on German wires. If they are not there, then a domestic cable is on the counter.

Additionally, it does not hurt to look at the material for filling the space between the veins - if there are streaks there, then this is a reason to doubt the use of chalk-filled rubber, which should be used according to the original standards.

Briefly about the main

Technical characteristics of NYM cable practically do not limit the scope of its application, provided that the cross-section and the protective sheath are selected correctly, if used outdoors. The products of the domestic factories "Sevkabel", "Kamkabel" and "Pskovkabel" are at least as good as their foreign counterparts in terms of conductive characteristics, but they can lose as a protective coating - if this parameter is important, then it is better to choose a cable made in Germany, Turkey or France. despite the price difference.