Probes (wires) for a multimeter - how to choose or make it yourself

Probes are an integral part of all multimeters, which is supplied with the measuring device, regardless of its model. Good styli have served their purpose over the years. But it also happens that a few days after buying a multimeter, one or even both contacts fail due to a wire break, breaking off the tip or cracking the insulation. To protect yourself from such a nuisance, you need to purchase high-quality and reliable multimeter probes, with good wires and strong tips. Many people generally prefer to make them on their own. In this article, we will talk about the varieties and features of these elements, and also figure out how to make homemade probes for a multimeter.

Content

Universal styli

These products are the simplest and cheapest. Most inexpensive multimeter models are equipped with them. The cables of these elements are PVC insulated and the plugs and lugs are made of plastic. A thin wire is attached to the steel electrode from the inside of the holder. These tips can easily come off if not handled carefully. It is clear that there is no need to talk about durability and high reliability here.

Different models of universal contacts have different lengths of the center electrode of the plug and the protruding part of its body. They also differ in the mounting depth of the plug.

Branded products

The multimeter is available with a variety of materials. High quality and reliable contacts can be distinguished by the following features:

- The test leads of the multimeter are made of highly flexible material.

- The holder entry is flexible and tight. The vein in it holds tight and does not give in to random jerks.

- The surface of the product near the base of the holder does not slip and is conveniently held with your fingers during measurements. The best option is a holder with a rubberized surface.

The video shows an example of such products:

All of these properties are possessed by silicone probes. These parameters are responsible for the high popularity of such products.

Often, the holder entries are made of plastic, but in this case they must have special recesses, otherwise the element will not have the required flexibility. On almost all branded models, the plugs and electrodes are equipped with caps that protect the elements from contamination and minimize the possibility of puncture injuries.

These products are designed based on the experience of using earlier models, therefore, they are thoughtful and easy to use. The wire of such contacts has a sufficiently high strength and flexibility, is resistant to accidental jerks and does not crack when bent.

SMD mounting probes

When working with SMD elements, it is periodically required to carry out measurements, which can only be dealt with using thin probes connected to the tester. These products are equipped with sharp brass or stainless steel needle-shaped tips. They are necessarily protected by caps, which minimize the risk of electrode fracture or accidental injury to the master.

For SMD installation specialists, such elements are the most convenient to work with. With sharp probes, you can not only pierce the insulation of the wire, but also scrape off the solder mask from the desired area of the board surface with further measurement work.Although the thickness of this needle is quite small, the cell can easily withstand 600 V for a long time.

For measuring work during the installation of SMD components, pliers are also provided for the multimeter. They allow you to measure the desired parameters of the part both on the desktop and directly on the board.

During the measurement, the component is clamped with forceps, which guarantees a good contact. These products have a short enough cable, but a long one is not needed to work with SMD.

If the measurement process requires maximum care in order to prevent the electrode from touching other parts, then it is best to use probes with holes at the ends.

With their help, you can make measurements both on printed circuit boards and during electrical work, without fear of accidentally provoking a short circuit.

Crocodile tips

This tip version is also available on the modern market and is in great demand. In some cases, it turns out to be preferable to sharp electrodes. The size of the "crocodile" can be different, but in any case, it must have a reliable shell made of dielectric material.

In the form of "crocodiles" can be made connecting tips, coming as an additional element for a standard probe. Often, the kit for the multimeter includes tips in the form of clip-on "crocodiles", which can be detached or fastened if necessary.

It is also necessary to mention the kits, which include several different tips. Getting to work, the master himself chooses the right one and screws it in like a nozzle. This possibility allows in some cases to significantly facilitate the measurement process. So, for example, a crocodile can be connected in turn to different parts of the tested electrical circuit, while the other tip is attached to ground as a terminal.

Lead component professionals prefer the lugs in the form of clips and hooks. With the help of such elements, it is convenient to carry out measurement work on printed circuit boards, as well as to hold in place during measurements the terminal components. These tips, as well as needles and crocodiles, can be supplied.

How to make homemade probes?

As we said above, many people prefer not to buy new ones when factory probes break down, but to make them on their own. Consider two popular options for making homemade products.

Standard DIY Probes

To make them, you will need collapsible fountain pens (without rods) and dart dart tips.

The procedure is as follows:

- Disassemble fountain pens and try on dart tips.

- After selecting the correct sized components, insert the dart tips into the handles instead of the rods, preheating them with a gas torch.

- Put a piece of solder inside the handle, having previously moistened it with soldering acid and warmed up.

- Lower the cable there.

- Wait for the solder to cool down and fix the probe elements.

The dart tip can be glued on for extra fixation.

Clearly the entire device on video:

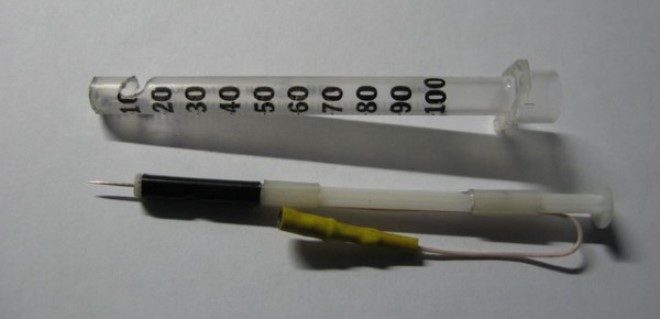

Thin homemade insulation piercing probes

Now let's figure out how you can make thin probes for a multimeter with your own hands. To do this, we need collet pencils using replaceable leads, and sewing needles that are suitable in thickness.

The manufacture of thin probes is as follows:

- Solder the cables to the pins.

- Insert the needles inside the pencils until they hit the center of the collet. So that when pressed, they do not go inside, they should be glued into the collet.

- Solder the plugs to the cables.

It is advisable to stretch a colored heat shrink on the resulting products. Be careful when working with a hairdryer, as the hot air flow can deform the plastic.

Pen and pencil caps can be used as protective elements.

In the video, an example of making needle probes for checking small parts:

Conclusion

From this article, you learned what test probes are for, what types of these products are and what are the features of their use. Well, those who like to independently assemble electrical devices and products will certainly be interested in information on how to make probes for a multimeter with their own hands.