Why do you need a junction box for electrical wiring

To some, a junction box for wiring will seem like a very insignificant element of a household electrical network. And really, what's the use of it? With the help of a switch, we control the lighting, we activate electrical appliances and equipment with sockets - there is a visible result from these elements of the electrical network. An invisible, but very important result is that switches, sockets and lamps are connected to the general electrical network through junction boxes. It is in them that the wires coming from the power source and going to the switching devices are connected.

Content

History of appearance

As soon as the first node was mounted, in which several wires of the branched electrical network were connected, the need for its protection immediately arose. First of all, from accidental contact of a person with a bare wire, which could lead to electric shock. Also required protection from external influences - mechanical, dust, dirt, water.

Even during the first steps of electrification, it was invented to protect the place of wire twists with a box. At first, for this purpose, improvised means were used, for example, cans from canned food. Holes were made in them, into which wires were inserted and twisted together. The most important thing was to carefully cut the holes, to make their edges smooth and not jagged, so that the insulation of the wires would not be damaged.

However, very soon electrical evolution led to the mass production of the necessary factory junction boxes by manufacturers. Although even now, after almost a century, somewhere there is a craftsman who, in the garage or in the shed, will connect the wires in a tin can.

Well, and you, if you are building a house or doing major repairs in an apartment, by all means start with electrical work. First of all, start installing junction boxes, do not use any cans and improvised tools, even in back rooms. Head to the electrical market, where boxes are sold in abundance - all sizes, configurations and degrees of protection.

Why is it called differently?

The electrical junction box received several names at once - distribution, wiring, branching, switching.

It is like an electrical distribution point, which receives voltage from a power source, and then diverges along several electrical branches - to sockets, switches, lighting fixtures. Because the voltage in the box is distributed in different directions, it was called distribution. Since several electrical branches leave the box, a synonym has appeared - branch.

Another name comes from the way the wires are connected inside the box. For a long time, soldering was considered the most reliable method. At the junction, the wires were twisted and then soldered, due to which electricians began to call the boxes unsoldered.

In an interesting way, another synonym arose - an opening box. The word "disconnect" can only be heard among professional electricians, and they came up with it, as if combining two concepts - distribution and connection. That is, they distributed in the box which wire and where it should go, and then they connected them according to the diagram.

Now there are so many modern connection options - all kinds of terminal blocks, welding, connecting insulating clamps, sleeve crimping, terminal blocks, self-clamping terminals.However, boxes are still often referred to as junction boxes.

We explained all this to you so that when you go to choose materials in electrical stores, and in different places you see different names, you know, they all mean the same junction box.

Is it always needed?

Quite a logical question, is it possible to do without a junction box? Theoretically speaking, yes.

Now imagine that from an introductory electrical panel, which is usually located at the entrance to a house or apartment, you will need to extend a separate line to each switch and outlet. How much wire is needed then? And the grooves will have to be made wide and deep so that you can lay several wires in them. So, from a purely economic point of view, the installation of junction boxes is a rational and expedient solution.

Someone may object and say that it is much safer to lay a solid line from the electrical panel to the switch or outlet, and there will be only an extra connecting node in the box. There is only one answer to this - a correctly and correctly made connection of wires does not pose any danger.

Everyone can have their own opinion on this matter, however, today the option using junction boxes is the most preferable one.

Kinds

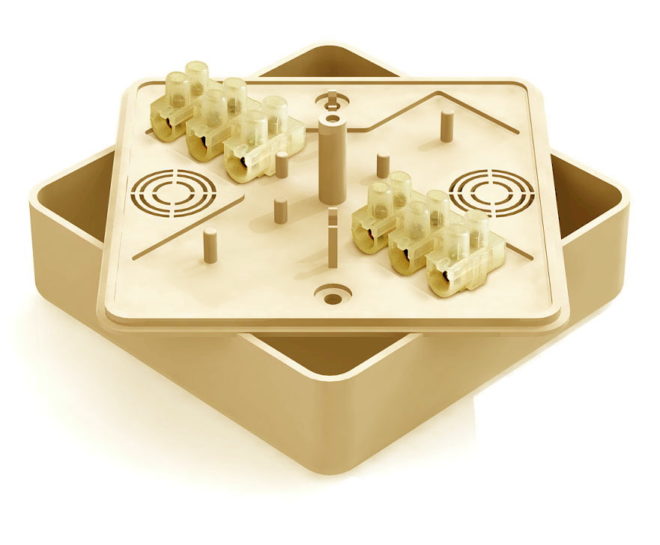

Boxes for connecting electrical wires come in different types and are classified according to many parameters.

By installation method

First of all, they are divided depending on the installation method:

- The junction box for surface wiring (otherwise called "outdoor installation") is mounted on wall surfaces. To install it, no preliminary preparation of the base is required. It is attached directly to the wall surface using various fasteners.

- The junction box for concealed wiring (called "indoor installation") is mounted in a special recess in the wall, which is drilled out during installation work. These junction boxes also differ depending on the material of the wall in which they will be installed. If in a concrete or brick wall, then it is necessary to make a recess with a special crown for the size of the box. In drywall or other sheet materials, a corresponding hole is simply cut out.

By material

Boxes differ depending on the material from which they are made. First of all, these should be materials that would provide maximum protection to the connected wires for the entire service life. In this regard, boxes for electrical wiring are made of high quality plastic and metals, on which a protective layer of anti-corrosion paint or primer is also applied.

For the manufacture of metal boxes, tin-plated sheet steel or aluminum alloys are used, which do not corrode. If a fire breaks out, the metal case will temporarily serve as a protection for the contents of the box, during which time at least it will be possible to de-energize the electrical network. Metal boxes are most often used in general buildings (garages, utility rooms, sheds).

Protect electrical connections and the plastic junction box just as effectively. For their manufacture, polyamide, polypropylene or cast fluoroplastic are used, these materials are not subject to decomposition by active substances. These plastic boxes provide excellent insulation against electric shock. In addition to good insulating properties, they also have sufficient mechanical strength. The plastic junction box is resistant to aggressive chemical liquids and can stay in a humid environment much longer than a metal one. If there is a danger of open fire, then the plastic does not burn, but melts, in this it, of course, is inferior to metal.

By other parameters

Junction boxes vary in size and the following criteria play a major role here:

- their purpose;

- number of inputs;

- protection class.

At least the box can have two inputs, that is, two wires will be connected in it. The maximum number of bushings in one junction box is 16. Accordingly, the more bushings, the larger the box is in size and depth.

Boxes differ in shape, they can be round, square and rectangular. For outdoor installation, it makes no difference at all which shape you use the box. But for internal installation, it is still better to take a round one, because if you have a concrete wall, then making a hole in it is much easier than hammering a square niche.

All of the above criteria add up to the price of the junction box. The price is also influenced by the degree of protection of this element:

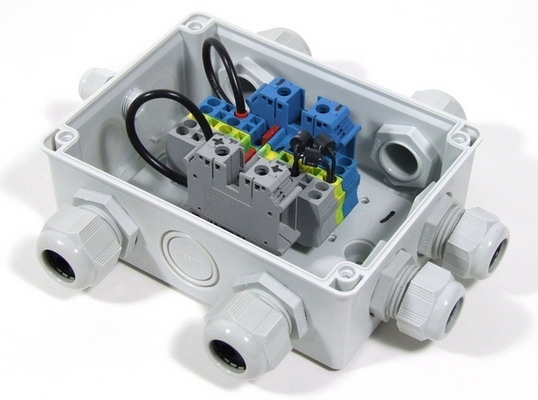

- IP 20, IP 30 - for use only in dry rooms, there is no protection against moisture;

- IP 44 - for outdoor use and in rooms with a high level of humidity, when installing outdoors, you must choose a place under a canopy or canopy, and avoid direct exposure to dust and water jets;

- IP 55 - for use in places subject to atmospheric precipitation, that is, boxes with this degree of protection can be installed outdoors in any conditions, they are completely protected from dust and water jets;

- IP 67 - for outdoor use in any atmospheric precipitation, as well as on the ground and in the ground;

- IP 68 - boxes with this degree of protection can be operated immersed in water, as a rule, the immersion depth is additionally indicated for each product on the package or case.

For household electrical networks, boxes with a degree of protection IP 55 are most often used.

Installation rules

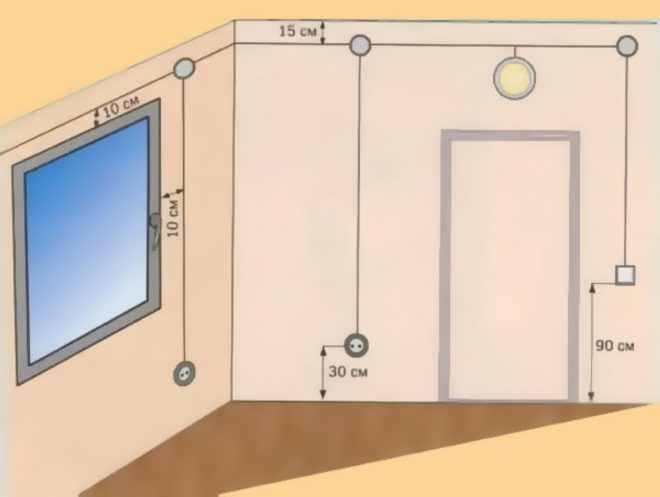

Before installing the junction box, familiarize yourself with the requirements prescribed in the main regulatory document of electricians PUE, as well as useful tips for installing junction boxes:

- The box should be installed at a distance of 10-30 cm below the ceiling level.

- The junction box must always be accessible. There are times when it was installed at the required distance from the ceiling, but then during a new repair and installation of stretch or suspended ceilings, the box was out of reach (that is, the ceiling level dropped). There is an option to leave a small hatch in the new ceiling for easy access to the box. But, most likely, it will not have a very attractive and aesthetic appearance. It is best to move it to an accessible place before making new ceilings.

- With a hidden version of electrical wiring, a recess is made in the wall for each junction box according to its size and shape (round or square). The depth of the niche is made such that the box then does not stick out of the wall, and when closed, the lid turns out to be flush with the wall surface.

- Outdoor models of boxes are mounted already on prepared decorated walls.

- If a high-quality repair has been made in the room, then I would not want to spoil its appearance with an unsightly lid covering the junction box. In this case, either arrange the cover to match your interior design (paste the wallpaper or paint to match), or choose a box with a decorative cover in advance.

- If you covered the box with wallpaper, be sure to remember its location in order to cut off the wallpaper at that place if necessary and gain access to the wire connections. It is best to keep an electrician's home journal, in which all the points of the boxes and the path of the wires in the grooves will be drawn. This is also very convenient in the event that you need to drill a wall for a picture or photo frame. Knowing the schematic wiring plan, you definitely will not stumble upon it with an electric drill.

- You need to look into the junction box not only when smoke is already coming out of it.Periodically, it is necessary to revise the connections for heating, as well as tighten the contacts.

Mounting

To install the box in the wall, you first need to prepare a hole. You will need a special tool, preferably a punch with a special attachment called a crown. What is it like? A ring with a victorious or diamond cutting edge. In the center there is a drill intended for concrete, it centers the crown, and already she herself cuts a round segment from the wall. Drilling is performed to the required depth, then the cut-out segment is removed from the wall using a chisel and a hammer (you can use a special blade that is installed on the perforator). In a similar way, a recessed niche is made for each installed element of the electrical network (sockets, switches).

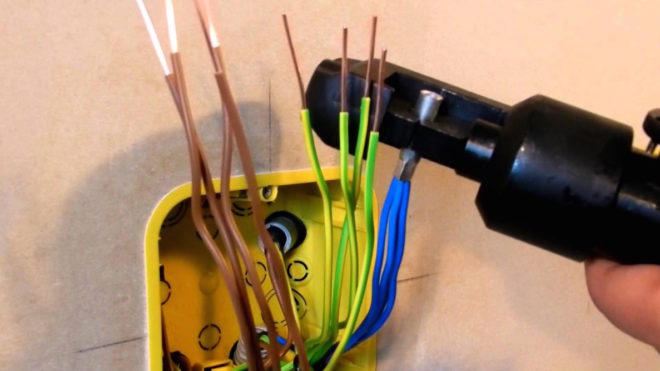

Then from the hole it is necessary to punch the grooves in which the wires or cables are laid. Their ends must be brought into the box (it has several special holes for this) and left sticking out 10-15 cm for mounting the connection.

Then the boxes are embedded in a niche on a solution of alabaster or stucco. It remains only to make all the necessary wire connections and close the installed element with a cover. The wires are connected by welding, twisting and subsequent soldering, crimping with sleeves or terminal blocks.

Now you know almost everything about junction boxes. Always start your power supply repairs with them. It is not a problem to purchase these elements of the power grid now, the main thing is to decide exactly which ones you need?