Cable and wire stripper

Carrying out electrical work requires a toolkit, which includes both conventional and specialized tools. One of them is an electrician's knife, which is often needed not only for specialists, but also for ordinary people who are going to do certain work related to electricity in a house, garage or country house. In the article, we will describe this tool in detail, talk about its varieties and nuances of use for electrical work. In addition, part of the material will be devoted to disclosing the question of how to make a knife for an electrician with your own hands.

Content

Features and benefits of a plumber's knife

This tool is intended for cutting cables, stripping them of primary insulation and stripping of insulating material from conductive wires. One of the main requirements for it is the presence of an insulated handle, without which working with electricity is fraught with consequences, up to and including serious electric shock. In addition, it must indicate the voltage rating of the insulation withstand. If the knife does not have such a handle, then it can only be used when working with de-energized lines.

It is undesirable to use long and too sharp devices during electrical work, otherwise unnecessary cables can be easily damaged if the wires are tangled. In addition, small and precise manipulations are best done with a short blade that feels good in the palm of your hand and is more comfortable in confined spaces.

If the cable has a double insulating coating, it is advisable to use a tool with a straight blade, the cutting edge of which is parallel to its main axis, if it is necessary to clean it from the outer sheath. Oblique knives are poorly suited for these actions.

Often, electricians use homemade knives, wrapping one of the edges of the canvas with a few electrical tape. It is clear that there is no need to talk about the high reliability of such insulation.

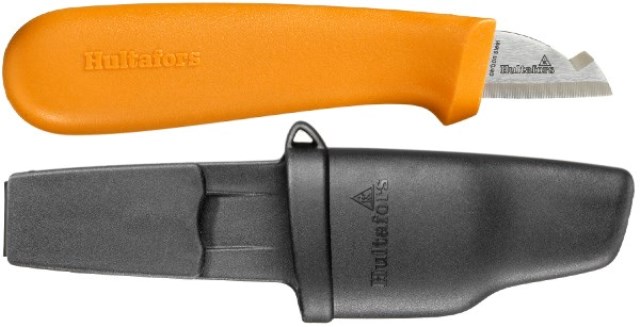

If a specialist works at height, while the necessary devices are in a special belt, you can use a cutting tool with a sheath. Such a knife can be fixed on the belt, it does not interfere with movement and at any time can be removed by hand by touch. The scabbard on a quality product holds tight and does not fall off from vibration, but at the same time it can be easily removed with one thumb. However, many fitters do not like to wear them on the belt, considering it uncomfortable.

However, the fact that the instrument is less blunt in the scabbard and it is easier to find it by touch when it lies in a heap of other devices is noted by almost all electricians.

Varieties of construction

Structurally, knives for stripping electrical wires can be folding or non-folding, with a straight or curved blade. In any case, the blade should be moderately sharp, it should not have burrs and notches, otherwise the conductors can be easily damaged when stripping the cable.

If a folding knife is used for electrical work, then it must be equipped with a reliable lock so that the blade does not fold spontaneously when stripping the cable. The blade must be sharpened on both sides. It is desirable that the cutting edge has an internal rounding - this makes it easier to strip the insulation from the wire.

As already mentioned, an electrician does not need a tool that is too sharp, since it is easy for them to cut their fingers, as well as damage metal wires. An overly sharpened blade can cause accidental damage to the insulation of the wrong wire, which is being processed.

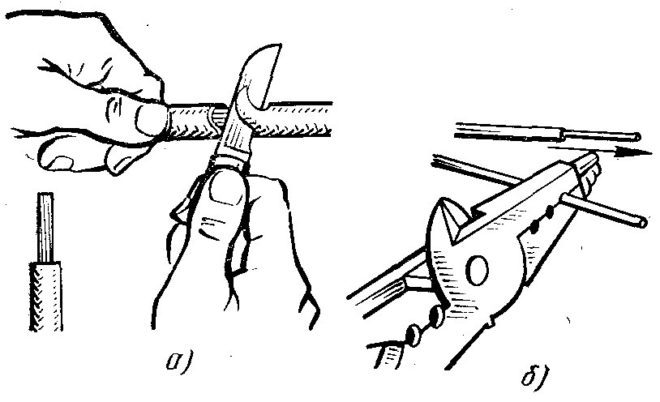

It is very important to strip the wire correctly. Many will cut the insulation around the circumference and then pull it off the core, but this often damages the metal part of the cable.

The insulating material should be cut with a motion similar to that used when sharpening a pencil.

Monter knives with heel

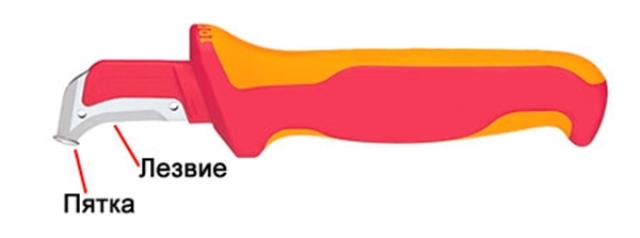

An electrician's knife with a heel is one of the types of cutting tools for electrical work. It has two main parts:

- Insulated handle with stop.

- Blade with a teardrop-shaped heel at the end.

The blade of such a cable stripper is rounded inward in the shape of a hook and has a short length. Its main task is to remove the primary insulation from the electrical wire. The heel, welded to the edge of the blade, avoids damage to the insulation of current-carrying conductors during operation.

This product is not intended for stripping the insulating material from the metal base of the conductor, and using it for this purpose will quickly lead to a loss of sharpness of the cutting edge and the formation of burrs on it.

It is best to use a stripper to expose the conductive strand.

A knife with a heel is a very handy tool that greatly simplifies and speeds up the cutting of an electrical wire. Modern devices made in the factory, in addition, have an attractive appearance and thoughtful design.

The ergonomic, insulated handle fits comfortably in the palm of your hand. It is equipped with rubberized inserts, thanks to which the mounting knife is firmly held by the hand and does not slip in it during operation. The handle of the tool has special notches for the thumb rest, which also contributes to a tight grip. The cutting edges of the product are sharpened both outside and inside, so the insulation can be cut by moving the knife in any direction along the cable.

The teardrop heel is worth mentioning separately. She, as mentioned above, is welded to the tip of the knife and avoids accidental violation of the insulation of live conductors during operation. When the blade cuts the outer sheath of the electrical cable, the heel slides inside it, preventing accidental damage to the insulation of the inner wires. Since the heel surface is carefully sanded, it itself cannot damage the electrical conductors when sliding.

Since any electrician, except a knife, carries a lot of other tools with him, to protect the blade, the device is equipped with a special cap that prevents direct contact with other products and the appearance of notches and other damage on the blade.

This cap is rather massive and, when put on the knife blade, fits snugly against its handle. Therefore, it is almost impossible to accidentally lose it.

How to make a knife with a heel yourself?

As we have seen, the heel-equipped utility knife is a very handy tool that has serious advantages. However, it does have one major drawback - its high cost, which makes it difficult for many people to afford such a purchase.

If you have to do electrical work only periodically, as is usually the case in a household, buying a specialized tool is inappropriate.

However, such an electrician's knife can be made with your own hands, this procedure does not present any difficulties. Let's take a closer look at how to complete it and what we need for this.

Materials for work

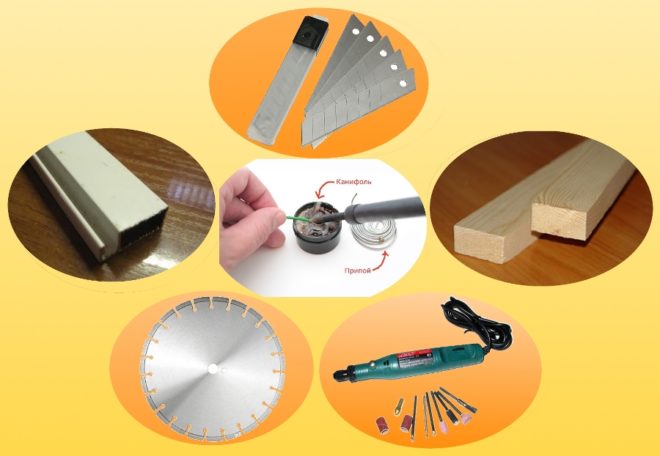

To make a homemade knife with a wire stripper heel, you first need to stock up on the accessories listed below:

- Blades for a stationery knife (2 pcs.)

- The aluminum profile from which the handle will be made. A piece of metal base from the mosquito net used in PVC windows is fine.

- A lath made of wood, which should be somewhat inferior to the profile in its cross section.

- Soldering iron with POS solder and phosphoric acid.

- Diamond cutting microdisc.

- Drill.

Having prepared all the necessary materials and tools, you can proceed directly to the assembly of the knife with the heel.

Manufacturing procedure

A homemade plaster's knife is made in the following order:

- Cut a spike on the clerical blade to which the heel will be attached.

- Grind off excess sharpening so that only the edge remains sharpened.

- Sharpen the opposite side of the blade.

- Make a heel with a slot from a piece of the second blade, which will correspond to the thickness of the cutting blade.

- Using a soldering iron and solder, attach the heel to the first blade. Give its edges an oval shape so that during the operation of the tool it cannot damage the insulation of the cores and their metal base.

- Insert the blade into a piece of metal profile and unfasten it inside using a wooden strip with a cut.

- Drill a hole in the handle so that it is aligned with the one already in the blade.

- Insert a bolt into the hole and secure on the other side with a nut.

This completes the work, the tool is ready to use.

A slightly different technology for making a knife with a heel in the video:

Conclusion

In this article, we looked at a tool that is so necessary when working with electrical wiring, like an electrician's knife, and also figured out how you can make it yourself without spending a lot of time and saving money. Of course, if you have to work with electricity every day at a professional level, it is better not to stint and get a good branded tool. But for household work, it is quite possible to do with homemade, if it is made correctly.