Cable ducts for wiring - what they are and where they are used

The use of open-type electrical wiring is not uncommon, especially in wooden buildings. Its main advantage is easy access to cables. At the same time, wires located in plain sight not only disrupt the harmony of the interior, but also create the risk of electric shock or fire. You can avoid this danger by placing the wiring inside special devices - the so-called cable ducts. In this article, we will analyze what cable ducts for electrical wiring are, what materials are used for their manufacture and how the process of installing these structures occurs.

Content

Purpose and types of cable channels

The main function of these devices should be called the protection of the wires located inside them from mechanical damage. Conditionally cable ducts are divided into two types:

- Tough. These boxes can be open, equipped with an easily removable lid or made in the form of skirting boards.

- Flexible. Such structures can be made in the form of sections, tubes or chains.

The material used for the manufacture of cable ducts must meet two basic requirements: to be highly durable and not subject to fire.

There is an additional criterion - the ability to electrical insulation, but it does not apply to mandatory, since often these protective structures are aluminum or made of galvanized iron.

The most popular cable ducts are made of PVC, in order to increase the strength of products mixed with hardeners.

Selection rules and video editing example:

Now we will consider in more detail the features of various types and understand the features of their device and application.

Rigid cable ducts

For the manufacture of rigid structures, metal or plastic (polyvinyl chloride) is used. The box may not be equipped with a lid, in this case there are mounting holes in its walls and bottom. Another option is blind structures with covers that do not have holes. In addition, there are combined cable ducts that do not have holes and are not equipped with covers.

The advantage of perforated boxes lies in their improved ventilation, and hence in the higher electrical conductivity of the conductor placed in them.

When choosing one or another type, one should take into account the installation location of the devices. For example, wiring, which is laid in a frame house, can be placed in a metal cable duct used for open lines.

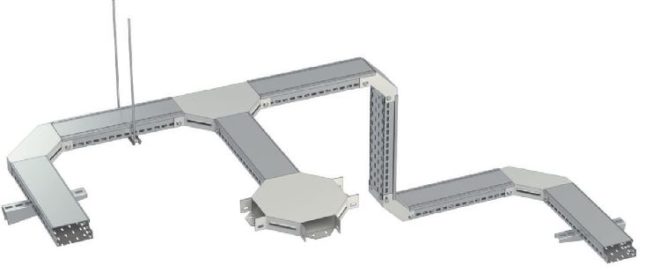

Such devices can be easily installed in ceilings and partitions, as well as in raised floors due to the ease of attachment. The box is fixed to the supporting structure with self-tapping screws, electrical wires are placed inside it and they are fixed to the box with plastic clamps.

Closed cable ducts for electrical wiring are most often mounted to walls or installed on the ceiling. They are fixed with self-tapping screws screwed into the mounting holes.

The cable ducts offered on the modern market have a variety of colors, so you can choose the products, the tone of which is best suited for a particular interior. The price of boxes does not depend on their color.But fixtures decorated with a pattern applied by the method of photoprinting are considered designer products and have a higher cost.

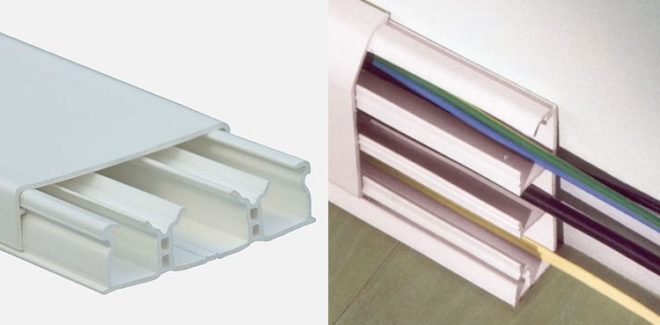

The cable duct is available in various sizes, these products are standard or wide. The latter are used in works related to multi-wire installation. To isolate each of the loops from the neighboring ones, wide cable channels are separated by partitions.

Features of hard channels

The most elegant are aluminum cable ducts. Appliances made in Italy and Germany are especially in high demand. They are completed with a cover imitating wood or other material on the outside.

The sizes of the sides of the products are different - from 70x100 mm to 600x1000 mm. The scope of the former is for alarm wiring in residential or business premises, and the latter are designed to protect thick cables. The width of the walls can also fluctuate between 0.7 and 2.4 mm.

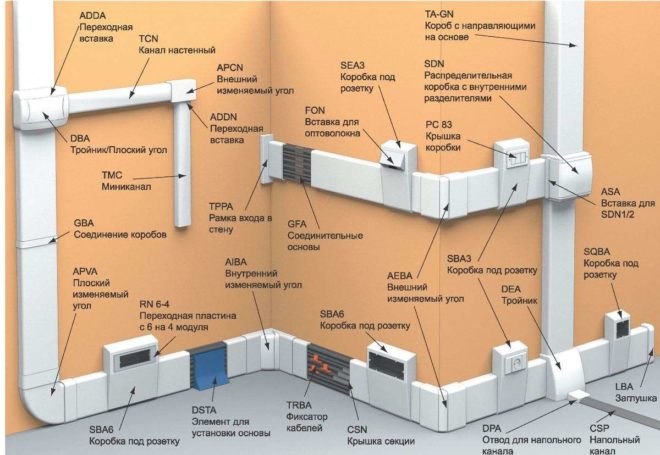

The delivery set of cable channels includes additional elements (turns, corners, crosses, etc.), which allow to give the structure a monolithic look during installation.

Flexible protective channels

The appearance of flexible protective channels was dictated by the need to conduct wiring along the walls of structures with architectural irregularities. If rigid channels are used under these conditions, they will exactly repeat the plane differences, which will ruin the appearance. If in brick or concrete buildings the walls can be more or less aligned, then in wooden buildings the traditional alignment is not applicable. In this case, flexible cable ducts will be an excellent solution.

There are the following types of flexible protection channels:

- Tubular. As a rule, they are used when moving to the door plane.

- Rubber.

- Flexible chains (called track links).

- Made from soft plastic by molding.

Since the production of flexible cable ducts is rather complicated and laborious, they have a higher price in comparison with rigid ones.

Tracks are widely used in private housing construction to connect small household machines, as well as in factories and factories in order to connect working equipment. The width of these devices can be from 20 to 234 mm.

Rubber cable ducts, like those made of soft plastic, due to their large wall thickness, provide reliable protection of electrical conductors from various damages. They are well suited for rooms with high humidity (except for a steam room in a steam bath or sauna).

The tubular channels are made of a metal strip twisted into a spiral. Its main advantage is the ability to bend in different directions without harming the structure. A flexible wire is laid inside the device. Typically, these channels are used to connect electric door locks.

Materials used in the production of cable ducts

For the manufacture of these products are used:

- Aluminum.

- Zinc coated steel.

- Plastic.

Plastic fixtures are usually installed on walls as well as under ceilings. Metal cable ducts can be floor mounted as they are resistant to high loads.

Types of cable channels in the video:

Galvanized steel

For the manufacture of protective devices from this material, a one-piece rolled profile, coated with zinc and painted with polymers, is used.

These channels are immune to fire. They are used for the installation of fire systems, as well as warning and video surveillance mechanisms.

The advantages of metal cable ducts include:

- High degree of protection of the electrical cable from external mechanical factors and electromagnetic waves.

- Ease of installation.

- Fire safety.

- The presence of an easily removable snap-on cover.

- Execution in various colors.

A metal shielding box is often used in office buildings for small-gauge cables, as it successfully replaces plastic fixtures.

Anodized aluminum

Aluminum cable ducts are most often used in warehouses, as well as in industrial enterprises when installing open lines. In more rare cases, they find a place in a high-tech home interior.

The main advantages of this material include:

- Resistance to electromagnetic impulses.

- Immunity to solar ultraviolet light.

- High impact resistance.

- Resistant to temperature extremes.

- Fire safety.

The weak point of this design is the complexity of the installation. Dowels are used to fix the channel and the cover, therefore, you cannot do without a special tool during installation.

Refractory plastic

Constructions made of this material are most widespread. Cables are laid inside a closed protective channel, which can have different cross sections - round, rectangular or triangular, as well as flat.

The fixtures are made in various colors and can be of any size.

The advantages of plastic structures include:

- Resistant to corrosion.

- Simple fastening mechanism.

- The ability to quickly cut a piece of the box to the desired length.

- Resistant to temperature extremes.

- Little weight.

Fixtures made of plastic are equipped with a cover that can be easily installed and removed without the use of tools.

Features of the installation of cable channels

Now let's figure out some of the nuances of installing protective boxes for electrical wiring - you need to know them in order to avoid mistakes during installation:

- Rigid structures should only be mounted on level surfaces.

- The installation should start from an electrical element or lighting fixture. Leading the channel from the junction box is an error.

- When joining the sections with each other, it is necessary to leave a gap between them in order to compensate for possible thermal expansion if necessary. This distance should be 1.5-2 mm.

- Installation of boxes on uneven walls should be carried out without tension so that the structure sags slightly.

- Fastening the channel to the plasterboard partitions should be done with small self-tapping screws with a flat head and a length of 1.5 cm.

- The spacing between the mounting holes should be between 30 cm and 50 cm.

- A metal hacksaw can be used to cut aluminum and steel ducts. Plastic and rubber boxes are cut with a sharp knife.

Visually about video editing:

The installation of protective cable channels is not a complicated procedure. Do it yourself or seek help from a professional electrician - everyone decides for himself.

Conclusion

In this material, we figured out what protective boxes for electrical wiring are for, and also considered different types of existing cable channels and the materials from which they are made. We hope that the knowledge gained will help you choose protective devices for the wiring of your home, and, if necessary, install them without assistance.