Wire stripper tool - what are their types and applications

One of the essential attributes of a professional electrician is a wire stripper. It can be called in different ways - stripper, cable cutting machine, and some mistakenly say "crimper". The last one is actually a separate crimping tool, but it is often part of the stripper: you get a universal device - a stripper-crimper - with which you can strip the insulation from the wires and immediately fix the connection.

Content

Why do you need stripping pliers

In addition to the main characteristics of professional tools, users estimate how much the speed of work and its quality increase when using them.

Even if you change the wiring of a typical apartment, then in each of the rooms (residential, kitchen, corridor, etc.) there will be at least one lighting lamp, one switch and several sockets, plus contacts in the introductory panel. Two or more wires are suitable for each of these points, so their total number will reach several hundred.

If modern repairs are being made in a large-area room, in which, in addition to lighting and power wiring, cables for the Internet, television, speaker systems and others are laid, then the number of contacts for which the wires must be stripped will easily exceed a thousand pieces.

Often, the wires need to be stripped to a certain length, for example, this is required when installing some branded sockets - otherwise, the core simply will not fit into the connector intended for it. Most pliers have the ability to adjust the length of the wire to strip, and rely on an eye to use a knife.

Even if you lightly hook a wire core with a knife blade, then such a conductor increases sensitivity to kinks, and the place itself with a scratch may begin to heat up. The insulation stripper, in turn, is made in such a way as to cut the edge of the sheath without reaching the core.

As a result, most customers may be suspicious of an electrician who lacks stripping pliers among their tools.

Varieties of strippers

Since the wires are used in the installation of electrical wiring of different brands and sections, several types of cable stripping tools are used to prepare them. The result of their work is about the same, but depending on the manufacturer, the reliability and durability will differ.

Depending on your skills, preferences and the amount of money that you can spend on buying a tool, you can choose automatic and manual strippers - each of which has certain pros and cons of use.

A variety of insulation strippers in the video:

For shearing off outer insulation

The work on stripping wire cores begins with removing the outer layer of insulation.Many cables have a rather "delicate" sheath and if you make a wrong move with a knife, the outer layer and the coating applied to the cores are cut through. There are a number of tools that are designed to cut the outer layer of insulation without snagging the sheathing.

Stripping knife

Although this stripping tool does not belong to the class of strippers, it is widely used in conjunction with them, since the latter, in turn, are primarily designed to work precisely with the inner cores of wires.

Outwardly, this cable cutting machine is a sickle-shaped double-edged blade, at the tip of which there is a smooth rounded sole - a heel.

Having made a minimal cut on the outer insulation, the heel is pushed under it and now you can cut the outer layer from the cable with one movement. Since the heel is smooth, it glides over the inner cable strands without causing any harm.

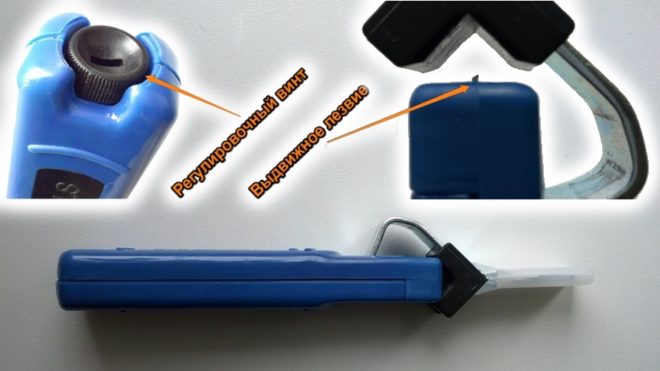

Stripper for stripping external insulation

In appearance, this device resembles a thick knife handle, with a flat surface at the end. A foot is brought to it from above, which presses the wire to the surface - the clamping force is regulated by a slider on the body. The insulation is cut with a blade that extends from the end against which the wire is pressed.

The depth of the slot is adjusted with a screw located at the opposite end of the tool.

The procedure is simple - the insulation cutting depth is set, a cable is inserted into the clamp, pressed against the surface with a foot and pulled to the required length. Then it remains to simply pull the insulation off the wire. This cable cutting machine is designed for round wires (in particular, NUM brand), but with certain skills it will be useful for flat wires.

Some of these tools have an additional knife (the one in the picture has it in a white plastic case), but practice shows that there is usually no sense from it and it is better to choose models without such an addition.

Semi-automatic strippers

The “semi-automatic” function means that such a stripper cuts the sheath of the wire to remove the insulation, and the person removes the resulting cambric from the core with an additional movement.

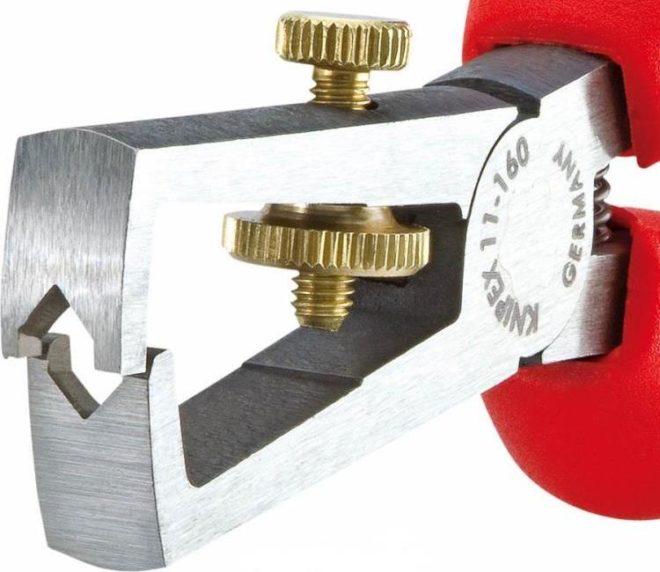

Stripping pliers

Outwardly, this tool resembles pliers - when the handles are brought together, the cutting edges also converge. This device is designed for fast processing of a large number of identical wires, up to 5 mm in diameter.

The pliers are manually adjusted to a certain core thickness by means of an adjusting screw - this is both their advantage and disadvantage. The downside is obvious - if in the process of work it is necessary to clean out several veins of a different diameter, then the pliers must be reconfigured first to them, and then back. Also, such tools often do not have a limiter for the length of the cut off section of insulation - you will have to measure it by eye.

The advantage of this solution is that, if properly configured, such stripping pliers are physically unable to damage the wire core. In addition, they can be adjusted to any wire thickness in the range of up to 5 mm - even if cables of not the highest quality are used for installation, which are made at the factory with a certain error in the thickness of the conductors. Also, the design of the pliers makes them the most convenient for working in hard-to-reach places and they can handle live wires. During editing, this property is used extremely rarely, but everything ever happens for the first time.

To remove the insulation, the wire is wound between the knives, the handles are compressed and now the core can be pulled out, and the cut cambric will remain inside the tongs.Some types of insulation can be quite viscous, therefore, to facilitate the work, the core itself (or pliers), after wrapping around it with knives, must be slightly turned around its axis. Then the insulation will be cut from all sides and removed much more easily.

Circular trimming knife

As with using a conventional knife, here you have to "feel" the tool so as not to hook the core, but still this design gives more freedom and significantly increases the speed of work.

Outwardly, such a tool resembles a regular paper stapler, but from the end and sides it has blades that cut the wire insulation. Cutters are also built into the body - it seems to be a trifle, but from time to time it helps a lot.

Depending on the required cutting method, the wire is threaded into a certain recess on the body (or through it, if the outer insulation is removed) and clamped with knives. Then a small turn is made around the axis and the resulting cambric can be removed.

An overview of such a device in the video:

Automatic strippers

These are the "fastest" tools used to strip wires. All that needs to be done when working with such devices is to insert the wire into the designated place and squeeze the handles of the tongs. The tool will independently determine the thickness of the wire, fix it and remove the insulation in the right place. According to the principle of action, they are divided into those that tear off the insulation and cut it off.

Cam strippers

Such a device has two pairs of cams, each of which is fixed on its own half of the pliers. A wire is laid between them, from which insulation must be removed. When the handles are squeezed, the upper cams move to the lower ones and press the wire against them, and then the tongs move apart. At the same time, the left pair of cams tightly wraps around and holds the wire, and the right pair is connected at a certain angle, partially pushing through the insulation. When the jaws of the pliers separate, the right pair of cams tears off a piece of insulation and the wire is stripped.

The advantage of this type of device is its ability to adapt to different wire diameters and the ability to strip several cores at once. Nippers and a crimper are often built into the handles of such pliers.

The principle of their work is clearly seen in the video:

Undercutting automatic strippers

These models are somewhat different from the previous device, but the basic principle of operation is generally the same. The main difference is that there are no cams - instead of them, knives cut the wire insulation behind the jaws. They also remove it from the vein.

It is also a fully automatic stripper that automatically adjusts to any wire diameter (0.2 to 6 mm).

What to choose for work

Selecting and separately recommending any one of the listed tools for stripping wires will be a deliberately wrong and ungrateful thing - each thing is good in its place and in its time. Usually, electricians keep at least one of all types of strippers - for external insulation, semi and automatic, but in general they try to collect all such tools - the cases are different, so they will not be superfluous.

The main thing when using insulation strippers is to periodically check the quality of their work - if, for some reason, the blades begin to cling to the wires, then everything will have to be redone.