Do-it-yourself wiring in a frame house - step by step instructions

Every year new and perfect frame technologies appear in construction. And even if you did not graduate from special institutes and did not study the profession of a builder, it will be possible to build a house yourself using a frame-frame or frame-panel method. Wiring in a frame house, first of all, must be safe and reliable. And in terms of aesthetics, it is desirable that it does not spoil the overall appearance, design and style inside the building. Therefore, we will consider all possible electrical options for a frame house.

Content

Layout

As with any other building, everything must first be carefully planned and schematically displayed on paper. Think about where the switchboard will be located, the entrance doors to the rooms, since switches need to be mounted near them. Decide on the location of lighting fixtures and household appliances so that the sockets are nearby, and then you do not have to throw the carriers across the entire room.

Calculate the loads in order to correctly select conductors in cross-section and switching devices for rated current. Also, such a layout will help you determine the amount of materials required.

Entering the house

There is a branch line from the main power line to your home. Its installation is carried out by air or underground. Depending on what voltage is needed (single-phase 220 V or three-phase 380 V), the cable is selected, it will be three-core (for 220 V) or five-core (for 380 V).

The lead-in cable comes to the electric energy meter, which, according to the new requirements, must be installed on the outside of the house so that the controller can take readings at any time without hindrance.

The meter should be located in a sealed shield or box to protect it from the effects of precipitation.

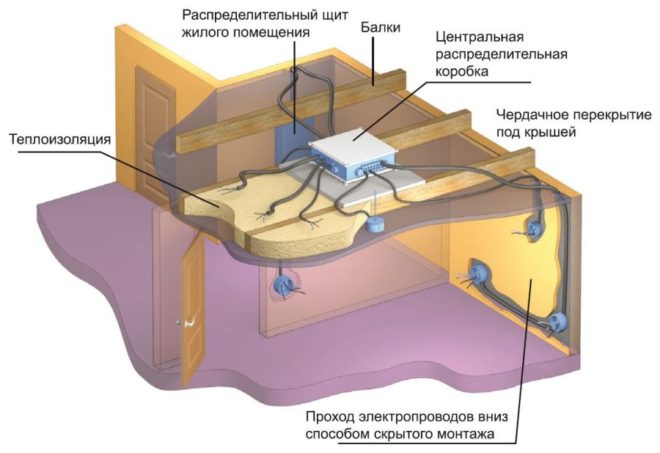

From the meter, the cable must be brought inside the house. To do this, a hole is drilled in the wall, if the house is two-story, then it is best to do this at the level of the interfloor floor. The cable is laid in a corrugated pipe, pulled through the hole made, fixed in the interfloor ceiling and then laid to the input distribution board.

Note! After the meter, there must be an automatic machine in the circuit, which will serve as protection for the cable going from the meter to the switchboard in the house. If there is a damage to this cable or a short circuit, then the protection will work - the machine will turn off. Otherwise (if there is no machine), the meter may burn out, and the entire trunk line will be disconnected somewhere in the TP or at the substation.

Distribution board

The lead-in cable goes into the switchboard and is connected to the lead-in machine, which in terms of power should be the same as the one on the street after the meter.

After the introductory machine, all switching in the switchboard is performed according to the diagram. Outgoing line automatic devices, RCD protection devices, differential automatic devices are connected. Ideally, two machines should be allocated to each room of a frame house (one for lighting, the other for connecting sockets). For premises such as a bathroom or a kitchen, it is necessary to install additional machines for energy-intensive household appliances.

What type of wiring to choose?

Wiring in such buildings can be done, as in ordinary houses, in two ways - external (or open) and internal (hidden).

The option of external wiring implies the installation of wires on wall and ceiling surfaces using special cable channels, electrical pipes or an open way. The routing is done when the main construction steps have been completed.

Hidden wiring in a frame house involves placing conductors inside walls and ceilings. Outside there will be only switches, sockets and ends of wires for connecting lighting fixtures.

The installation of such a wiring is combined with construction, while the walls inside the house are not sheathed with anything.

Video example:

Each method has its positive and negative sides.

The main advantage of the internal wiring is that it is aesthetic, all conductors and connections are hidden, nothing spoils the appearance of the room. She has much more disadvantages:

- Any switching device (socket or switch) is installed completely, you can no longer move it somewhere to a new place.

- It is not possible to periodically inspect and assess the condition of the power grid.

- Internal wiring is materially more expensive than external wiring, and it also requires considerable physical costs.

- Insurance companies do not run the risk of concluding contracts for timber frame houses with internal electrical wiring.

- There is no possibility of installing additional points (for example, if you need another outlet in some room).

The main advantage of outdoor wiring is its availability, that is, it is visible and you can control its condition. Accordingly, there is a possibility of repair, at the right time you can replace not only the switch or socket, but also the wires.

Outdoor wiring can be branched to add points for new appliances.

The disadvantages of the external wiring option include the fact that it does not always fit organically into the overall interior of the premises. Also, when the wires are visible, the risk of damage increases.

As you can see, all arguments are inclined towards the fact that an outdoor electrician in a frame house is preferable. In addition, statistics show that fires occur more often in buildings with hidden wiring.

External wiring

Do-it-yourself external wiring in a frame house is done without any problems, there are several options for it.

Open cable

A rigid cable with a double or triple insulating layer made of non-combustible materials can be used. Such a conductor is attached to wall surfaces with special brackets. Between the wall and the cable, an asbestos or metal backing must be laid, which must be 1 cm wider than the conductor on both sides. This is a reliable and economical way of laying, but not entirely aesthetically pleasing, especially if several cables must be placed side by side.

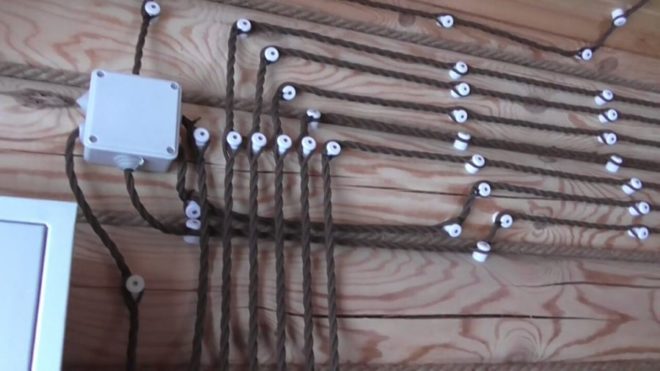

When the design of the premises is made in a retro style, twisted wires on ceramic or porcelain rollers (insulators) will look nice and original.

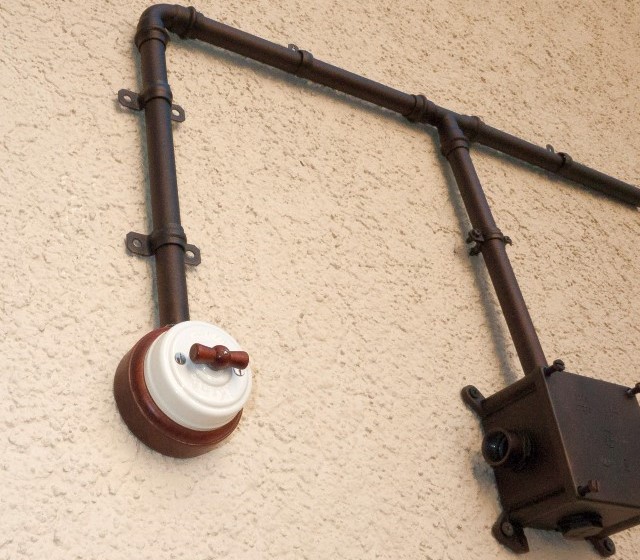

Electrical pipes

It is possible, when laying wires outside, to place them in electrotechnical corrugated pipes, for the manufacture of which special non-combustible materials are used. Several conductors can be placed in the pipes at the same time; they are attached to the walls using special clips. Such wiring looks compact, besides, the pipe insulates the cable from flammable wall surfaces and protects from possible external damage. But the pipe does not look at all presentable, besides, it collects dust on itself too well, which is practically impossible to clean.

Cable channels

Cable channels will look much neater than corrugated pipes. Moreover, now on the market of electrical goods, you can pick them up for any interior (they are available in different colors).

The disadvantage of cable ducts is that they make the curvature of the wall surfaces noticeable.

But since it is hardly possible to find curved plastered walls in a frame house (gypsum plasterboards or lining are most often used), laying wires in cable ducts is considered a good option.

Cable ducts are plastic boxes that are attached to walls and ceilings with glue or self-tapping screws. For their manufacture, high-quality refractory plastic is used. They come in different widths, depending on how many cables and what cross section are simultaneously laid in them. When the conductors are laid in the boxes, they are closed from above with locking covers. An example of such a posting in the video:

Another disadvantage of using cable channels is that over time, the frame house shrinks, and plastic boxes may crack. In this case, the electrical wiring will have to be redone. But at the same time, there are advantages of this method of laying - it is cheap and easy to install.

Internal wiring

The most important regulatory document of an electrician is PUE (rules for electrical installations). According to these rules, internal wiring (it is also called hidden in another way) in wooden houses must be carried out in metal pipes. Since frame houses are made of wood, this requirement must be observed for them as well. Can you imagine what financial costs such a number of pipes and their installation can result in?

Metal sleeves or boxes can be used, but if money allows, still use pipes. These auxiliary devices must have a wall thickness of 2.5 to 4 mm (depending on the cross-section of the conductors) so that in the event of a short circuit, the metal structure does not burn out. It is advisable that the pipes inside are painted or galvanized, this will protect the walls from rust. Video example:

Naturally, there will be bends and turns on the way of laying the cable; in these places, the pipes should be connected by welding or threading. It is very convenient to use copper pipes, they bend easily, but it is too expensive.

In order not to damage the insulating layer of the cable, plastic sleeves are mounted at the ends of the pipe.

Such an installation is performed even at the construction stage, moreover, as you can see, it is quite costly both in terms of finances, and in terms of labor, time and effort. Therefore, the most correct choice for a frame house is still external electrical wiring.

Quality materials

Before you make the wiring, you still have to choose and buy materials. Remember that the reliability and safety of your home's power supply directly depends on their quality.

If, in order to bring electricity to the house, a rigid aluminum wire (such as self-supporting insulated wire) is quite suitable, then it is recommended to carry out all the wiring inside the building with a flexible copper cable.

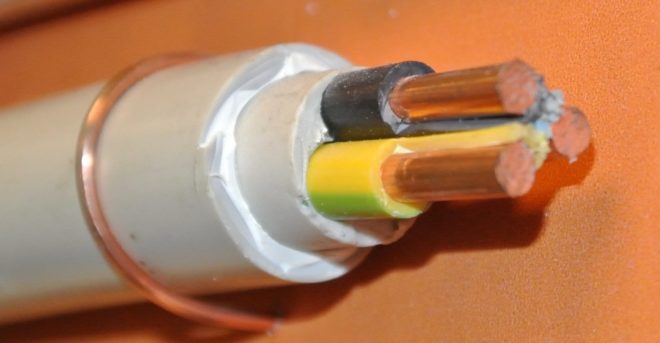

The best option would be NYM brand cable. It is marked 3x1.5 mm2, where the first digit "3" means that this conductor consists of three cores, one of which is the phase, the second is zero, the third is grounding (most often it is yellow).

The figure "1.5" means the cross-section of each core. A cable of this size is just right for all lighting wiring. To connect the sockets, you will need a larger conductor (2.5 mm2), and for energy-intensive household appliances, such as an oven, a water heater, it is better to take a cable with a cross section of 4-6 mm2.

To install sockets and switches in a frame house, you should choose metal mounting boxes.

If you have the time, effort, experience and knowledge for such a responsible decision, how to build a house yourself, then the electrical wiring in a frame house will be within your reach. But in case of the slightest question, consult with experts. Still, with electricity, you can never switch to "you", the safety of human life depends on it.